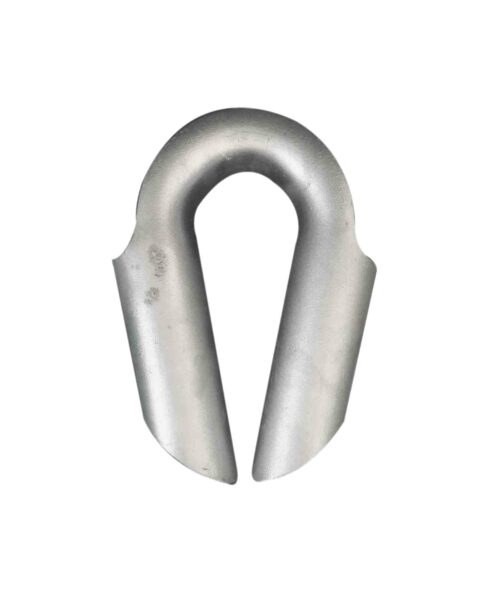

—————————————Wire Rope Thimble—————————————

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Fittings

Wire rope fittings are components and accessories used to terminate, connect, or enhance the functionality of wire ropes in various applications, such as lifting, rigging, and suspension. These fittings play a crucial role in creating secure connections, preventing fraying, and facilitating the attachment of wire ropes to other equipment.

Some common types of wire rope fittings

-

Thimbles: Thimbles are protective inserts made of metal or plastic that are placed inside the loops or eyes formed at the end of a wire rope. They help maintain the shape of the loop, reduce wear, and provide a smooth surface for the rope to bend around. Thimbles can be used with wire rope clips or swaged fittings.

-

Wire Rope Clips (Cable Clamps): Wire rope clips are metal fittings used to secure the loose end of a wire rope back to the body of the rope to form an eye or loop. They consist of a saddle, a U-bolt, and nuts. Proper installation involves placing the saddle over the rope, threading the U-bolt through, and tightening the nuts. Wire rope clips are commonly used for non-permanent terminations.

-

Swage Fittings: Swage fittings are designed to be permanently attached to wire ropes through a swaging process, which involves compressing and deforming the fitting onto the wire rope. Swage fittings can include end fittings, terminals, and studs, providing a strong and secure connection. Swaging requires specialized equipment and is often done by professionals.

-

Turnbuckles: Turnbuckles are devices with two threaded eye bolts connected by a central body. By rotating the central body, the distance between the two eye bolts can be adjusted, providing a means of tensioning and adjusting the length of a wire rope. Turnbuckles are often used in applications where periodic tension adjustments are necessary.

-

Wire Rope Ends: Wire rope ends, also known as flemish eyes or spliced ends, involve creating an eye or loop at the end of a wire rope by splicing the individual strands. This method provides a smooth and strong termination point without the need for additional fittings.

China Wire Rope Thimble Supplier

Kailipu is a top wire rope thimbles manufacturer and supplier in China. We supply various kinds of thimbles. Among them, the European type DIN6899B, US type G411 and G411 are the most representative. And our thimble specifications from 3mm to 130mm, which covers almost all sizes you will need.

Wire rope thimbles, also called cable thimbles. It is a common wire rope fittings. People usually use it to protect the eyes of cable, and rope slings from abrasion. Also it can provide a solid steel barrier between the fragile cable strands and the other rigging fitting used in the connection. Meanwhile, according to different used wire ropes, we have multiple types of thimbles for you to choose from.

We also have a full production line. Not only can produce the standard type, but also do custom production. If you are looking for a professional rigging and wire rope fittings supplier, do not hesitate to contact us.

Related Categories

FAQ

We usually use thimbles to protect the eyes of cable and rope slings from abrasion. Also they can provide a solid steel barrier between the fragile cable strands and the other rigging fittings. Meanwhile, thimbles can also prevent eye deformation or kinking by giving structure to the cable eye.

US type thimbles usually comes in two different duty grades, Light Duty and Heavy Duty.

Light Duty Thimbles

Light duty thimbles are typically used in static applications. Such as a permanent installation and a controlled environment.

Heavy Duty Thimbles

Heavy duty thimbles have extended protective material around their edges. It also have a tendency to resist deformation in uncontrolled applications. They are ideal for lifting, towing, and applications that will require the user to frequently connect and disconnect the thimble to other rigging components.

When sizing the thimble to wire rope, it’s important to size the thimble to the actual size of the rope that you are using with it. For example, if you are using 1″ uncoated cable, use a 1″ thimble.

We offers thimbles that are made from zinc plated steel, hot dipped galvanized steel, and 316 or 304 stainless Steel.

Among these, Stainless steel thimbles are best suited for being used in outdoor applications. And are highly resistant to rust. For hot dipped galvanized thimbles, their cost are lower than stainless steel. And They also suited for outdoor environments. The last one, zinc plated thimbles, we can also use it outdoors. But the zinc coating is thinner than a hot dipped galvanized coating.