———————————————Wire Ropes———————————————

Coated Wire Rope

Coated Wire Rope

Coated Wire Rope

Coated Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

Lifting Wire Rope

What Is Steel Wire Rope?

Wire ropes also known as steel wire rope, steel cables. And we mainly use them in hauling and lashing heavy duty cargo. It is an advanced engineering product that can find use in many areas such as mines, oil drilling wells, constructions, bridges, stadiums, etc. Steel wire ropes are manufactured to withstand very high weights. Many rope knitting techniques have been developed to increase durability.

Classification Of Wire Ropes

Steel wire ropes are classified based on various factors, including their construction, purpose, and application. The classifications help users select the most suitable wire rope for a specific use, taking into consideration factors such as strength, flexibility, resistance to abrasion, and environmental conditions.

Here are some common classifications of steel wire ropes:

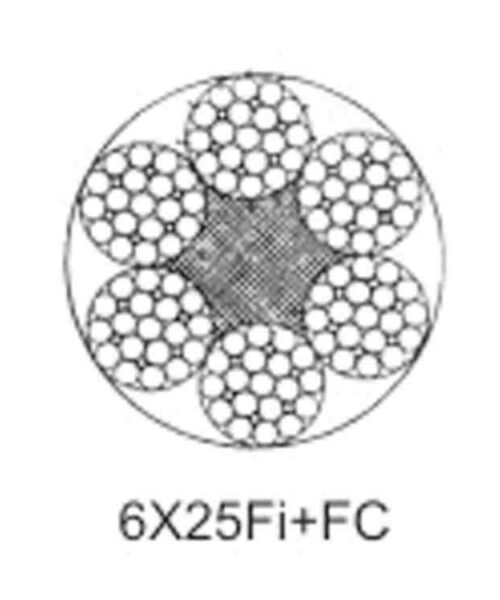

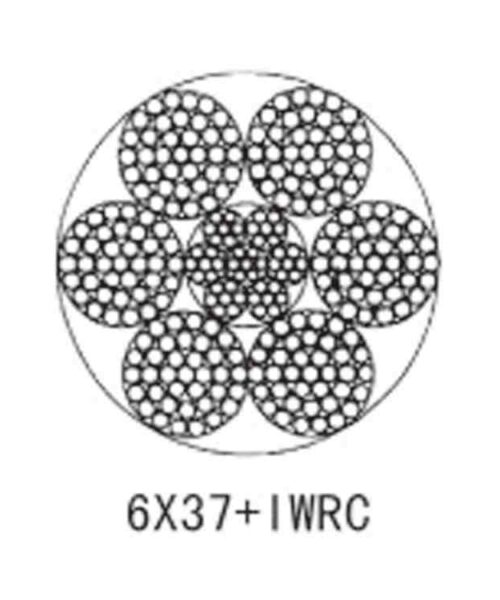

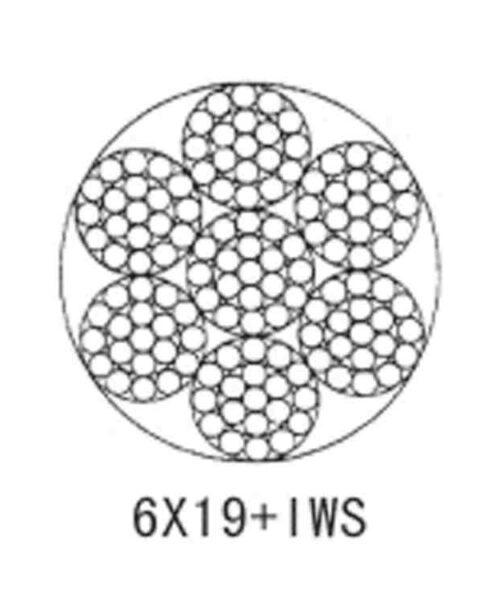

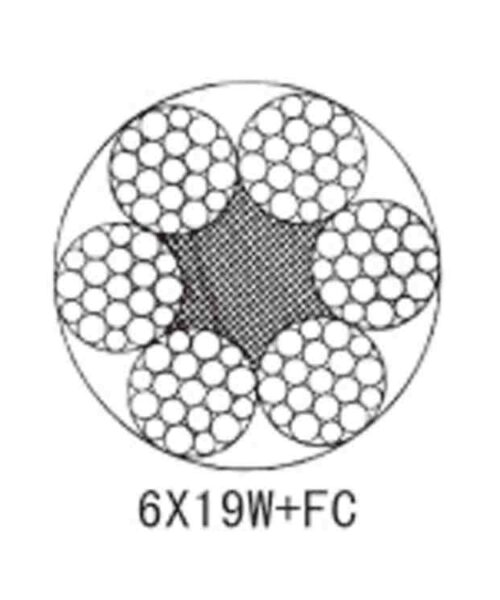

Construction Type:

Core Type:

Purpose or Application:

Surface Coating:

Professional China Wire Rope Supplies

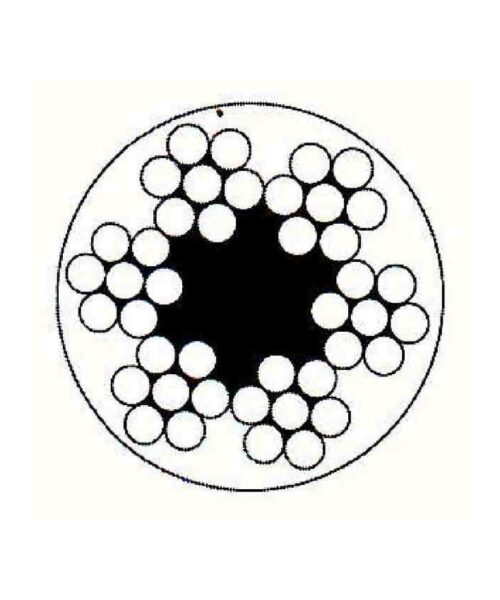

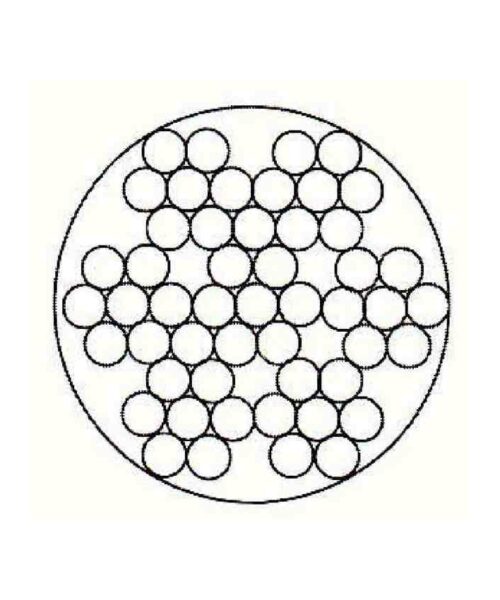

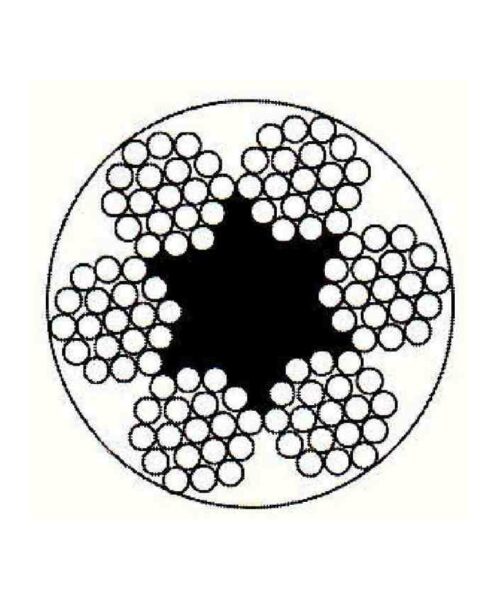

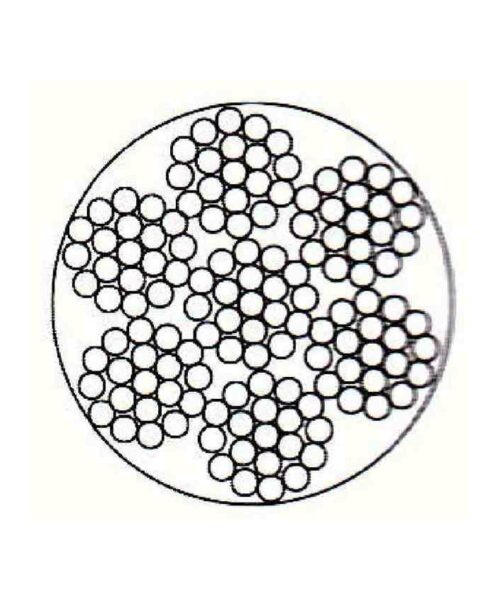

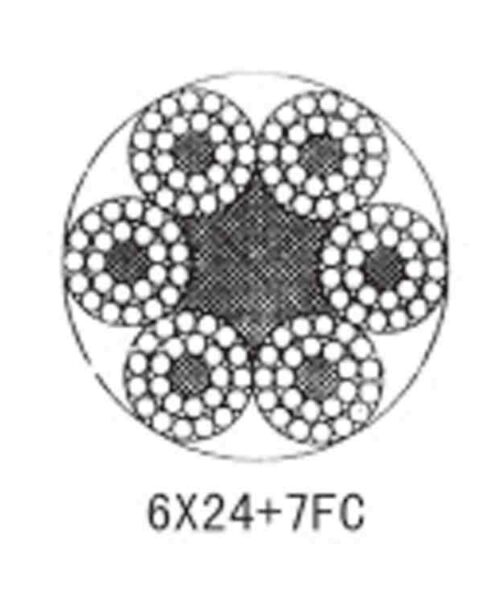

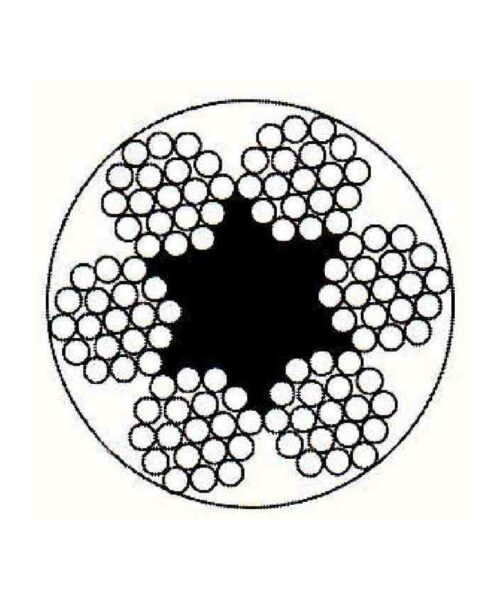

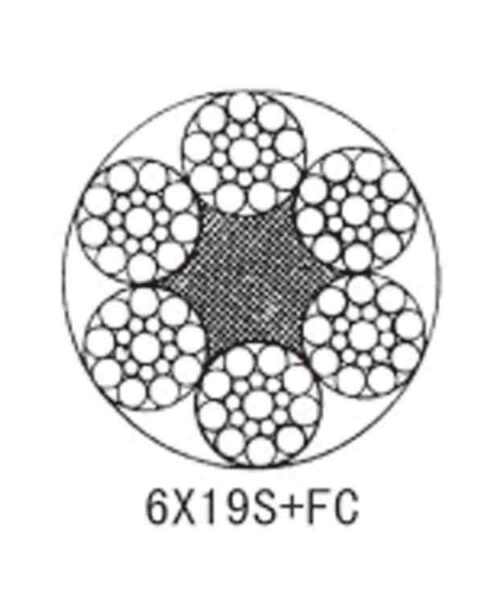

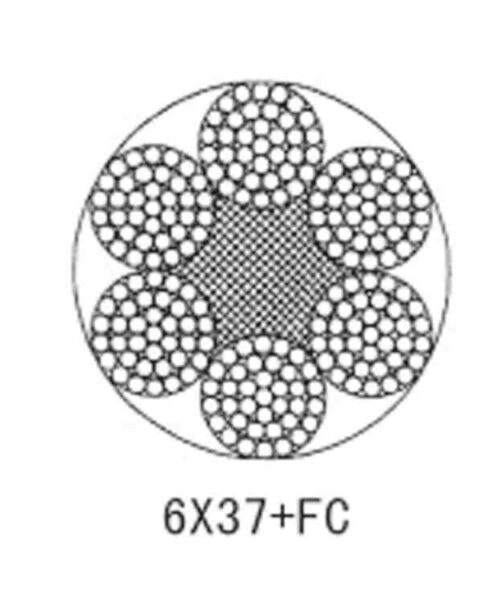

Kailipu supplies various kinds of steel wire ropes. Among them, the 6×7, 6×19, 6×24 are the most representative.

Our company has always made it a principle to work with a focus on customer satisfaction with its wide range of steel cable products. Our principle is always, Abundant Materials, Reasonable Price and Timely Delivery. Being reliable is an indispensable criterion for KAILIPU.

If you are looking for professional wire rope supplies or steel cable supplier, do not hesitate to contact us. Kailipu will work with you to make better lifting, rigging, lashing products.

Related Categories

FAQ

For wire rope the packaging is generally in a coil, plywood or wooden reel. And the length can be according to customer’s demand.

The common surface treatment process for steel wire rope include : oil-coated, hot-dip galvanized, electro-galvanized, and plastic-(PVC) coated.

In the surface treatment of steel wire, oil is the most widely used one. Because oiling can not only play the role of rust prevention and lubrication, but also the price is relatively cheap.

Another type, hot-dip galvanized, it is to coat a layer of zinc on the surface of the steel wire rope through heat treatment. Usually, the hot-dip galvanized zinc layer is relatively thick, which can guarantee that it will not rust for 20 years in the air.

The third type of electro-galvanized steel wire rope is less rust-resistant than hot-dip galvanized. Generally, it can keep rust-free in the air for 3-5 years, but the electro-galvanized surface will be brighter than the hot-dip galvanized surface.

Finally, plastic-coated steel wire rope. This is to coat a layer of pvc on the surface of the wire rope, which has the effect of lifting buffer and wear resistance.