Weld-on Lifting Point Grade 80 Alloy Steel Forged D-Ring with Piovting Link

- Size: From 1.12T to 20T

- Material: Alloy Steel

- Processing: Forged

- Finish: Painted

- Packing: Cartons + Pallets

Weld on Lifting Point

A Weld on Lifting Point is a heavy-duty lifting accessory designed to be permanently attached to equipment or structures by welding. It serves as a secure attachment point for lifting slings, chains, or hooks, making it ideal for industrial, construction, and marine applications where robust and reliable lifting solutions are required. These lifting points are engineered to handle high loads and ensure safety during lifting operations. Available in various load capacities and designs, weld on lifting points are widely used in environments where fixed lifting points are necessary to enhance operational efficiency and safety.

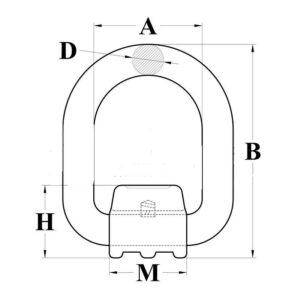

Specifications:

| Size(inch) | WLL | MBS | Weight | Dimensions(mm) | ||||

| (T) | (T) | (Kg) | A | B | D | M | N | |

| 1.12T | 1.12 | 4.48 | 0.40 | 41.0 | 78.5 | 13.0 | 37.0 | 35.0 |

| 2T | 2.00 | 8.00 | 0.47 | 42.0 | 88.0 | 14.0 | 40.0 | 37.0 |

| 3.15T | 3.15 | 12.80 | 0.69 | 45.0 | 94.0 | 17.0 | 42.5 | 40.0 |

| 5.3T | 5.30 | 21.20 | 1.46 | 55.0 | 118.0 | 22.0 | 50.0 | 52.0 |

| 8T | 8.00 | 32.00 | 2.50 | 70.0 | 141.0 | 26.5 | 65.0 | 57.0 |

| 10T | 10.00 | 40.00 | 3.59 | 85.0 | 165.0 | 28.0 | 78.0 | 63.5 |

| 15T | 15.00 | 60.00 | 5.79 | 97.0 | 188.0 | 34.0 | 90.0 | 77.0 |

| 20T | 20.00 | 80.00 | 15.50 | 150.0 | 250.0 | 46.0 | 130.0 | 98.0 |

WARNING:

Loads may disengage from link if proper welding,assembly, and lifting procedures are not used.

A falling load may cause serious injury or death.

Do not use with damaged slings or chain. For sling inspection criteria see ASME B30.9.

Read and understand These instructions before welding on, or using the pivoting link.

Key Features of Weld on Lifting Point:

High Load Capacity: Designed to handle heavy loads, ensuring safe and secure lifting operations.

Durable Construction: Made from high-strength materials like forged steel, ideal for harsh environments.

Permanent Attachment: Welded onto equipment or structures for a reliable, fixed lifting point.

360° Rotation: Many weld on lifting points allow for full rotation, ensuring flexibility during lifting operations.

Corrosion Resistant: Available in corrosion-resistant finishes for use in marine or outdoor settings.

Safety Tested: Manufactured to meet international safety standards for lifting equipment.

Applications of Weld on Lifting Point:

Construction Industry: Used on machinery and structures for safe and efficient lifting of heavy components.

Marine Sector: Ideal for shipbuilding, offshore platforms, and port operations requiring secure lifting points.

Manufacturing: Frequently used in factories and workshops for moving large industrial equipment.

Mining: Ensures safe handling of heavy mining machinery and tools in demanding environments.

Transport and Logistics: Facilitates the lifting and securing of cargo, equipment, and machinery in transit.

Weld On Lifting Points for Distributors Worldwide

At Kailipu, we supply high-quality, durable lifting points designed for heavy-duty applications across multiple industries, including construction, marine, and manufacturing. With competitive pricing, fast global shipping, and products built to meet international safety standards, we are the trusted partner for your bulk orders. Contact us today to discuss your requirements and start offering premium lifting solutions to your customers! We are always there for you! For any more help, e-mail our specialists at [email protected] for assistance.

Related Links: