The Ultimate Guide to retractable straps

Introduction

Whether you’re moving furniture, securing a motorcycle, or transporting equipment, retractable straps are an essential tool for ensuring your load stays in place. In this guide, we’ll dive into what ratchet straps are, how to use them, and why they’re indispensable for any job requiring secure load management.

What are Retractable Straps?

Retractable straps, also known as ratchet straps or tie-down straps, are fasteners used to hold down equipment or cargo during transport. These straps are typically made of durable polyester webbing and feature a ratcheting mechanism that allows for maximum tensioning.

Components of a Ratchet Strap:

- Webbing: The strong, woven fabric that wraps around your cargo.

- Ratchet: The mechanical device that tightens the strap.

- Hooks: Often found at the ends of the strap, used to anchor the strap to a fixed point

Why Use Retractable Straps?

Retractable straps provide several advantages over other types of fasteners:

- Strength and Durability: Made from high-quality materials, they can handle heavy loads.

- Adjustability: The ratcheting mechanism allows for precise tensioning.

- Versatility: Available in various lengths and weight capacities for different applications.

- Ease of Use: Simple to operate with a bit of practice.

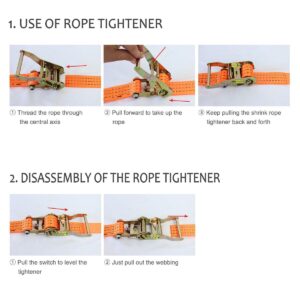

How to Use Ratchet Straps

Step-by-Step Guide:

- Anchor the Hooks: Attach the hooks on each end of the strap to fixed points on your vehicle or trailer.

- Position the Webbing: Place the strap over your cargo, ensuring it’s centered and covers the load securely.

- Feed the Webbing: Pull the loose end of the strap through the ratchet’s mandrel (spool).

- Tighten the Strap: Pump the ratchet handle to tighten the strap, ensuring it’s secure but not overly tight to avoid damaging the cargo.

- Lock the Ratchet: Once tight, lock the ratchet in place to prevent it from loosening during transport.

Pro Tips:

- Avoid Twists: Ensure the webbing is flat to distribute tension evenly.

- Inspect Regularly: Check the straps periodically during transport for signs of wear or loosening.

- Release Carefully: To release the strap, pull the release lever and open the ratchet completely.

Types of Ratchet Straps

Light-Duty Straps: Ideal for securing smaller items like bicycles or light furniture.

Medium-Duty Straps: Suitable for appliances, medium-sized equipment, and motorcycles.

Heavy-Duty Straps: Designed for large, heavy loads such as machinery and vehicles.

Specialty Straps:

- Axle Straps: For securing vehicles by their axles.

- Endless Loop Straps: Without hooks, these are perfect for bundling and securing objects tightly together.

Maintenance and Safety Tips

Storage: Store ratchet straps in a cool, dry place away from direct sunlight to prevent material degradation.

Inspection: Before each use, inspect for frays, tears, or damage to the webbing and hardware.

Proper Use: Never exceed the working load limit of the strap. Always follow manufacturer guidelines for safe use.

Training: Ensure all users are properly trained in the correct use of ratchet straps to avoid accidents.

Conclusion

Ratchet straps are an essential tool for anyone involved in transporting cargo. Their strength, adjustability, and ease of use make them a reliable choice for securing loads of all sizes. By following proper usage and maintenance guidelines, you can ensure your cargo arrives safely and securely every time.

Related Posts:

Reliable Retractable Straps Supplier in China

Kailipu is a leading supplier and exporter of lifting and rigging equipment in China. We offer a complete range of high-quality slings for rigging and lifting work. If you’re looking for a great ratchet tie down and straps supplier, let Kailipu be your first choice. Browse our website or contact our team at [email protected], Kailipu will work with you to make better rigging and lifting products.