MOORING CHAINS

Mooring chain is a critical component used to anchor vessels, platforms, and other marine structures to the seabed or dock. Known for its durability and strength, mooring chains are designed to withstand the harsh marine environment, including exposure to saltwater, strong currents, and high winds. They come in various grades, including U1, U2, U3, and even R3 to R5 for offshore and deepwater applications, offering different levels of tensile strength and corrosion resistance. Commonly used in ship mooring, offshore platforms, and permanent harbor installations, mooring chains are essential for ensuring the safe and secure positioning of vessels and structures in both calm and extreme sea conditions. These chains are available in both stud link and studless designs, with stud link chains providing added strength for heavy-duty applications.

Classification Of Mooring Chains

Mooring chains are classified based on their strength, application, and manufacturing standards. The classification typically depends on the chain’s grade, material properties, and usage in marine and offshore applications. According to the application mooring chains can be divided into Ship Mooring Chains, Offshore Mooring Chains, Permanent Mooring Chains, Temporary Mooring Chains, etc.

Ship Mooring Chains

Ship mooring chains are designed to secure ships and vessels to docks, buoys, or the seabed to prevent drifting due to currents, tides, or wind. Depending on the size and type of vessel, different grades of mooring chains are used.

Applications:

Anchoring Ships: Used to connect the anchor to the ship for stable positioning.

Docking: Secures the vessel to docks, harbors, or quays when stationary.

Temporary Mooring: Often used in marinas and harbors where ships dock temporarily.

Key Characteristics:

- Made from durable materials like steel.

- Resistant to corrosion and wear from saltwater.

- Grades U1, U2, and U3 are most common depending on the size of the vessel and environmental conditions.

Example Uses:

Small Boats and Yachts: Often use Grade U1 or U2 mooring chains for light to medium duty.

Commercial Ships and Tankers: Prefer Grade U2 or U3 for enhanced strength and durability.

Offshore Mooring Chains

These chains are specifically used for anchoring offshore structures such as oil platforms, floating production storage and offloading (FPSO) units, and offshore wind farms. The extreme forces in deep water require chains with high tensile strength and resistance to harsh marine conditions

Applications:

Anchoring Offshore Platforms: Chains are used to secure floating oil rigs, drilling platforms, and wind turbines to the seabed.

Deepwater Mooring: Chains are vital for securing equipment and floating structures in deeper waters where forces from waves and currents are more intense.

Key Characteristics:

- Use high-strength grades like Grade R3, R4, and R5, which are designed to withstand extreme stresses.

- Often galvanized or coated to resist corrosion from seawater and prolonged submersion.

- Can be stud link or studless, depending on specific use cases.

Example Uses:

Oil & Gas Platforms: Heavily rely on Grade R3 to R5 stud link chains to ensure stability and safety.

Floating Storage Units (FSUs) and FPSOs: Use high-grade mooring chains for extended mooring in harsh environments.

Permanent Mooring Chains

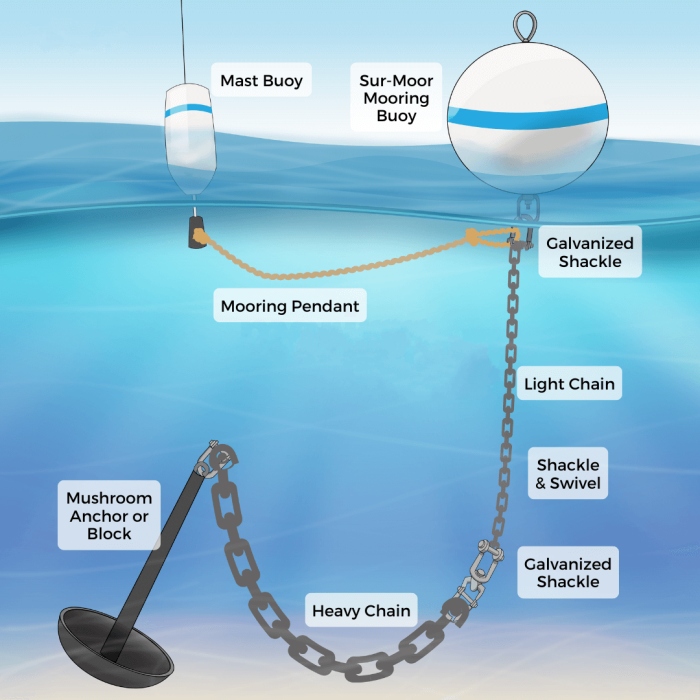

These chains are used in long-term or permanent installations such as buoys, ports, and harbor facilities. They are usually part of a larger mooring system that allows ships or offshore structures to remain anchored for extended periods

Applications:

Mooring Buoys: Chains are used to anchor buoys, which ships can tie to when docked offshore.

Harbor Infrastructure: Chains are used as part of the permanent docking system at ports and harbors.

Navigational Markers: Chains secure floating markers that help in navigation.

Key Characteristics:

- Generally Grade U2 or U3 chains are used, offering long-term durability.

- Requires corrosion-resistant materials or coatings due to constant exposure to water.

- Stud link chains are commonly preferred for their high strength and ability to prevent deformation.

Example Uses:

Port Mooring Systems: Ports use heavy-duty Grade U3 chains to secure vessels in harsh weather.

Navigational Buoys: Use corrosion-resistant mooring chains for stability and long-term functionality.

Temporary Mooring Chains

Temporary mooring chains are typically used for short-term mooring applications, such as when a vessel is anchored temporarily offshore or while waiting for docking space. These chains are generally lighter and used in less demanding conditions.

Applications:

Temporary Anchoring: Chains secure vessels in open water temporarily.

Floating Structures: Temporary mooring for barges, pontoons, or floating work platforms.

Short-Term Docking: Used by vessels while waiting to dock or load cargo.

Key Characteristics:

- Usually Grade U1 or U2, depending on the weight and size of the vessel.

- Lower tensile strength compared to permanent mooring chains but still reliable for short-term use.

- Lighter and easier to handle.

Example Uses:

Yachts and Small Vessels: Use Grade U1 chains for temporary anchoring in marinas or calm waters.

Fishing Boats: Use temporary mooring chains for quick deployment during fishing operations.

Mooring Chains-Stud Link Chains vs. Studless Chains

Depending on the application, mooring chains can be classified into stud link or studless chains:

Stud Link Chains: Commonly used in heavy-duty applications such as ship mooring and offshore platforms. The stud within each link provides additional strength and prevents the chain from deforming under heavy loads.

Applications: Ideal for permanent mooring, offshore mooring, and large vessel anchoring.

Studless Chains: Lighter and typically used in less demanding environments like temporary moorings or smaller vessels. Without the internal stud, these chains are easier to handle but may deform under extreme stress.

Applications: Best for short-term anchoring, small boats, and applications where ease of handling is important.

Certification Standards

Mooring chains are often certified by classification societies to ensure they meet specific safety and performance standards. Common certification bodies include:

- Lloyd’s Register (LR)

- Bureau Veritas (BV)

- American Bureau of Shipping (ABS)

- Det Norske Veritas-Germanischer Lloyd (DNV-GL)

- China Classification Society (CCS)

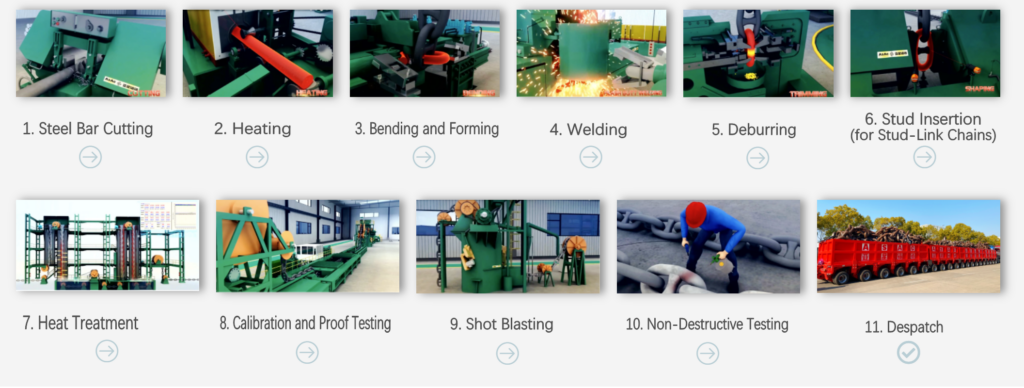

The Production Process

Kailipu- The Main Supplier Of Mooring Chain In China

Kailipu has established itself as a leading supplier of high-quality mooring chains in China, renowned for its commitment to excellence in manufacturing and customer service. With advanced production techniques, stringent quality control, and adherence to international standards, Kailipu provides a wide range of mooring chains, designed to meet the diverse needs of the marine industry. Kailipu’s studless chains are trusted by shipbuilders, offshore platforms, and maritime operators worldwide for their strength, durability, and corrosion resistance. By continuously innovating and maintaining competitive pricing, Kailipu stands out as the go-to choice for reliable mooring chains in the global market.

Browse our website or contact our team at [email protected], Kailipu will work with you to make better Rigging, Lifting, Material handling products.