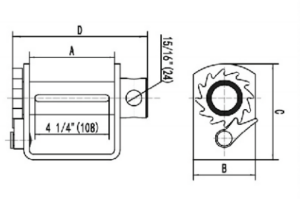

Low Profile Weld-On Truck Tie Down Winch

Size:

Bracket Height 140mm, Plate Thickness 8mm

Bracket Height 160mm, Plate Thickness 8mm

Bracket Height 110mm, Plate Thickness 8mm

Material: Carbon Steel

Color: Black painted

Packing: Carton +Pallets

Low Profile Weld-On Truck Tie Down Winch(side mount)

| Description | A | B | C | D | Net Weight | |||||

| mm | in. | mm | in. | mm | in. | mm | in. | KG | LBS | |

| Bracket Height 140mm, Plate Thickness 8mm |

124 | 4.84 | 90 | 3.51 | 140 | 5.46 | 196 | 7.64 | 3.44 | 7.57 |

| Bracket Height 160mm, Plate Thickness 8mm |

124 | 4.84 | 90 | 3.51 | 160 | 6.24 | 196 | 7.64 | 3.65 | 8.04 |

| Bracket Height 110mm, Plate Thickness 8mm |

124 | 4.84 | 100 | 3.9 | 110 | 4.29 | 196 | 7.64 | 3.32 | 7.31 |

Kailipu-China supplier manufacturer of Weld-On Truck Tie Down Winch

Truck Tie Down Winch The Low Profile Weld On Winch is also known as a “side Mount” winch. It’s welded to the side of flatbed trailers.

This low profile weld-on winch is designed to be permanently mounted in a fixed position. The low profile winch is for side mount applications.Black powder coated to protect against abrasion and rust. Features a low profile design for easy applications.

Kailipu – China Manufacturer, Supplier, Factory of trailer winches

Various Types of Trailer Winches & How Does Winch Works

Winches are synonymous with cargo control in the flatbed trucking industry. No matter what kind of open-deck trailer is being used, a truck driver relies on strategically located winches to tie down the cargo using webbing straps. A trailer needs enough types of trailer winches to meet federal tie-down standards dictating the required number of straps for each load.

Know the Types of Trailer Winches

1. Standard Welded Winch

The industry standard is the tried-and-true welded winch. It comes in a variety of sizes and is remarkably simple in its construction. It consists of the main body along with the winch axle, ratchet, and gear. There is a hole in the axle just outside the main body designed to accept a standard winch bar.

This particular winch gets its name from the mounting method. In other words, it is welded directly to the rail of the trailer. It can be mounted horizontally on the outer edge of the rail or vertically on the underside. The obvious benefit here is strength. On the downside, welded winches are fairly permanent.

2. Bolt-On Winch

The bolt-on winch looks a lot like a welded winch except that the rear plate is slightly larger to accommodate heavy-duty bolts. It works the exact same way as a welded winch in function. The main difference is that it is bolted to the rail rather than welded.

This sort of winch can be moved around if necessary. But there is a downside. Every position you might want to locate this winch requires drilling bolt holes.

3. Stake Pocket Winch

The stake pocket winch offers the flexibility you do not get from welded and bolt-on winches. Considered temporary winches, you use them by sliding them into the stake pockets along the rail of the trailer. Wherever you have a pocket, you can insert one of these winches.

Stake pocket winches are deployed in seconds thanks to a spring-loaded hook built-in to the bottom. Retract the hook, slip the winch into the pocket, and let go. The spring-loaded hook will return to its normal position and lock the winch in place.

4. The Slide Winch

Last but not least is the slide winch. The slide winch looks a little bit different in that it has a purpose-designed plate that slips into a rail already mounted on the side of the trailer. Upper and lower lips built into the rail hold the winch in place. By the way, there are both single and double sliders. The double slider utilizes a double rail with upper and lower sections.

The biggest advantage of this kind of system is flexibility. It can adjust to accommodate any load configuration. The downside is having to mount rails on the trailer. More can go wrong with this sort of system.

Conclusion

As you can see, there is more than one kind of winch. It is up to you to determine which ones are best for you. Note that we have everything you need here at Kailipu, from winches to webbing straps and ratchet straps.

Kailipu – China Manufacturer, Supplier, Factory of tie down winch, rigging hardware, welded chain,and webbing slings

Related products

Slide Winch

Bolt-On Winch

Weld-On Winch

Manual Winches