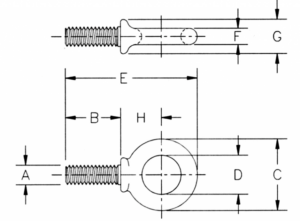

S279 Shoulder Type Machinery Eye Bolt

Material: Forged Steel

Processing: Drop Forged,Quenched and Tempered

Finish: Hot Dipped Galvanized

Size: from 1/4 ″ to 1-1/2″

Safety Factor: 5:1

Packing: Cartons or Gunny Bags and then on Pallets.

S279 Shoulder Type Machinery Eye Bolt

| Size (in) | Working | Dimensions (mm) | ||||||

| load | ||||||||

| limit (t) | A | B | C | D | E | F | G | |

| 1/4 x 1 | 0,29 | 6.35 | 25.9 | 28.7 | 19.1 | 58 | 4.85 | 13.5 |

| 5/16 x 1 1/8 | 0,54 | 7.94 | 29.2 | 35.1 | 22.4 | 69.5 | 6.35 | 15 |

| 5/8 x 1 1/4 | 0,7 | 9.53 | 32.3 | 41.1 | 25.4 | 78 | 7.85 | 17.5 |

| 1/2 x 1 1/2 | 1,18 | 12.7 | 38.9 | 49.5 | 30.2 | 94 | 9.65 | 23.1 |

| 5/8 x 1 3/4 | 2,35 | 15.9 | 45.5 | 60.5 | 35.1 | 113 | 12.7 | 28.7 |

| 3/4 x 2 | 3,26 | 19.1 | 52 | 70 | 38,1 | 129 | 16 | 35.1 |

| 7/8 x 2 1/4 | 4,08 | 22.2 | 58.5 | 82.5 | 44.5 | 149 | 19.1 | 39.6 |

| 1 x 2 1/4 | 6,03 | 25.4 | 65.5 | 95.5 | 51 | 169 | 22.4 | 46 |

| 1 1/4 x 3 | 9,52 | 31.8 | 78.5 | 114 | 63.5 | 202 | 25.4 | 58 |

| 1 1/2 x 3 1/2 | 10,8 | 38.1 | 91.5 | 140 | 76 | 241 | 31.8 | 70 |

Machinery eye bolts are designed with a shoulder and are designed for angular loading.

The difference between machinery eye bolts, regular eye bolts and shoulder type eye bolts is that the shank and threads of the machinery eye bolt do not protrude through the base metal.

Therefore, all of the holding strength of the machinery eye bolt is on the threads.

Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements.

Importantly, these bolts meet other critical performance requirements including fatigue life, impact properties and material.

Related products

Eye Bolt Nut

G43/G70 Hooks

Wire rope clips

Grade 80 Hooks

Wire rope clips

G43/G70 Hooks

Grade 80 Hooks

Shackles