Tube Thimble | Tube Wire Rope Thimble Without Gusset

- Material Options: Galvanized Steel, Stainless Steel, Mild Steel

- Standard: DIN, ASTM, or custom specifications as required

- Size Range: From 10mm to 140mm (custom sizes available on request)

- Finish: Galvanized (zinc-plated), Stainless Steel (passivated), Plastic spraying

- Shape: Tubular without gusset for enhanced reinforcement.

- Applications: Termination of wire ropes in lifting, rigging, and securing loads.

Tube Thimble | Tube Wire Rope Thimble Without Gusset

Tube thimbles are essential components used to protect and reinforce wire rope loops, enhancing their durability and performance under load. Designed for heavy-duty applications, these thimbles are widely used in industries such as marine, construction, and heavy equipment rigging, where they provide added safety and longevity to wire rope assemblies.

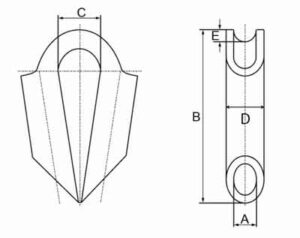

Technical Specifications

| A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | Rope diameter(mm) | Weight(kg) |

| 10 | 90 | 23 | 16 | 6 | 8 | 0.18 |

| 12 | 90 | 23 | 20 | 8 | 10 | 0.24 |

| 15 | 105 | 27 | 25 | 10 | 12 | 0.41 |

| 17 | 115 | 27 | 25 | 10 | 14 | 0.39 |

| 19 | 120 | 32 | 29 | 12 | 16 | 0.6 |

| 22 | 140 | 35 | 32 | 15 | 18 | 0.75 |

| 25 | 180 | 45 | 37.6 | 16 | 22 | 1.4 |

| 28 | 180 | 45 | 42 | 16 | 24 | 1.75 |

| 30 | 195 | 47 | 44 | 18 | 26 | 2.2 |

| 35 | 215 | 60 | 49 | 21 | 32 | 2.6 |

| 40 | 240 | 65 | 54 | 23 | 35 | 2.95 |

| 45 | 260 | 70 | 60 | 27 | 38 | 3.85 |

| 50 | 280 | 75 | 64 | 27 | 44 | 4.4 |

| 55 | 298 | 85 | 69 | 29 | 50 | 5.1 |

| 60 | 300 | 88 | 75 | 30 | 54 | 5.9 |

| 65 | 312 | 88 | 79 | 31 | 56 | 6.6 |

| 70 | 332 | 90 | 84 | 31.5 | 60 | 7.1 |

| 75 | 350 | 94 | 90 | 32 | 65 | 8 |

| 88 | 450 | 130 | 108 | 45 | 72 | 20.1 |

| 94 | 500 | 150 | 114 | 50 | 80 | 24.8 |

| 107 | 550 | 190 | 127 | 52 | 92 | 30.4 |

| 112 | 600 | 200 | 140 | 70 | 96 | 50.4 |

| 120 | 650 | 220 | 152 | 76 | 104 | 68.8 |

| 127 | 660 | 220 | 159 | 78 | 110 | 70 |

| 140 | 750 | 240 | 180 | 90 | 115 | 110 |

- Heavy duty stainless steel marine grade tube thimble. These thimbes can be used with stainless steel wire rope and also none steel ropes. The tubular design makes sure the thimble is always captive and avoids loss.

- Easy To Use. Let the wire rope pass through the U groove and then clamp it.

Key Features of Tube Thimble

Heavy-Duty Construction: Engineered for demanding environments and high-load applications.

Corrosion Resistance: Available in galvanized steel or stainless steel to withstand harsh environments.

Enhanced Rope Protection: Prevents wear, fraying, and deformation of wire ropes.

Range of Sizes: Suitable for various wire rope diameters.

Smooth Finish: Reduces abrasion on wire ropes, extending lifespan.

Applications

Marine & Offshore: Ideal for mooring and towing applications in marine settings.

Construction & Infrastructure: Used in heavy lifting, hoisting, and securing applications.

Industrial Rigging: Perfect for securing loads and providing reinforced connections in rigging tasks.

Forestry & Agriculture: Suitable for reinforcing wire rope connections in agricultural and forestry machinery.

Mining & Excavation: Essential for wire rope protection in rugged, heavy-duty mining applications.

How to Use:

- Step 1: Select the appropriate tube thimble size based on the diameter of your wire rope.

- Step 2: Insert the wire rope into the tube thimble, ensuring a secure and snug fit.

- Step 3: Secure with appropriate wire rope fittings (clips or swage sleeves) to lock the rope in place.

- Step 4: Inspect the setup to confirm proper alignment and secure load distribution.

Benefits of Choosing Tube Thimbles

Increased Safety: Provides secure reinforcement for wire rope loops, minimizing risks of fraying.

Extended Rope Lifespan: Reduces abrasion and wear on wire ropes, resulting in cost savings.

Versatility: Applicable across various heavy-duty industries, offering flexibility in usage.

Cost-Efficiency: Enhances wire rope longevity, minimizing replacement frequency.

Ensure the durability and safety of your rigging setup with our high-quality tube thimbles. Kailipu specializes in the production of various rigging and wire rope fittings. Contact us today for bulk orders and competitive pricing on industrial-grade tube thimbles. Contact our team at [email protected], Kailipu will work with you to make better Rigging, Lifting, Material handling products.

Related Links:

Related products

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire rope clips

Wire rope clips

Shackles