———————————————Lifting Chain———————————————

Lifting Chain

Lifting Chain

Lifting Chain

Lifting Chain

Lifting Chain

Lifting Chain

Lifting Chain

Hardware Chain

Hardware Chain

Hardware Chain

Hardware Chain

Hardware Chain

Lifting Chains: These chains are specifically design for lifting heavy loads using welding techniques. We use them in various industries, such as construction, manufacturing, and transportation, for hoisting and moving heavy objects.

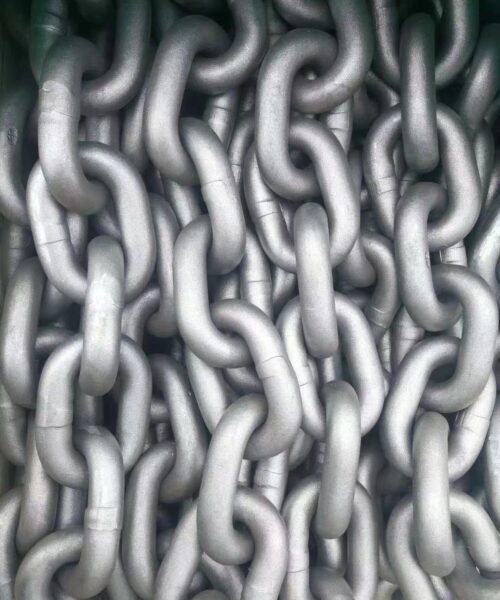

Professional Lifting Chain Manufacturers in China

Kailipu is a top lifting chain supplier and exporter in China. And we supply various kinds of lifting chains. Among them, the grade 80 and 100 alloy steel chains standard EN818-2, EN818-7 and NACM2010 are the most representative.

Lifting chains are commonly available with different load capacities and sizes to suit various lifting applications. They are typically mark with the WLL, which is usually indicate in tons or kilograms.

We have a full set of lifting chain production equipment, which can produce various standard types. Meanwhile, we can also do custom production according to your size. If you are looking for professional lifting chain manufacturers, do not hesitate to contact us at [email protected]

Which Chain Grade Should Be Used for Overhead Lifting?

We usually use Alloy Chain Grade 80 or Grade 100 for overhead lifting. ASTM states that alloy chain shall be able to elongate a minimum of 20% before fracture (7.3.5). And to ensure that alloy chain consistently meets this requirement, ASTM requires The use of certain alloying elements in the manufacturing of the steel for alloy steel chain. However, these alloys can vary from company to company.

The three governing bodies of USA Lifting Chain Manufacturers are OSHA, ASME & ASTM. People set these safety standards in order to ensure the safety of their employees and the quality of the chains they manufacture.

Related Categories

FAQ

Lifting chains are primarily designe for lifting heavy loads in various industries. They are engineer to withstand high loads and provide a reliable lifting solution.

When identifying a lift chain, it’s essential to carefully inspect the chain for markings and characteristics. Such as grade, WLL, material and finish. If in doubt, consulting the manufacturer’s documentation or contacting the manufacturer directly. To get further clarification and ensure the safe and proper use of the lift chain.

Lifting chains are typically not assigne specific grades. But we usually use Alloy Chain Grade 80 or Grade 100 for overhead lifting. Apart from ASTM states that alloy chain shall be able to elongate a minimum of 20% before fracture (7.3.5). And to ensure that alloy chain consistently meets this requirement, ASTM requires the use of certain alloying elements in the manufacturing of the steel for alloy steel chain. However, these alloys can vary from company to company.

The three governing bodies of USA Chain Manufactures are OSHA, ASME & ASTM. People set these safety standards in order to ensure the safety of their employees and the quality of the chains they manufacture.