High Tension Round Link Chain For Mining

• Standard: GB/T12718-2009

• Quality grade: C

High Tension Round Link Chain For mining

High-tension round link chain for mining are specialized chains designed for use in mining and other heavy-duty applications where robust and reliable equipment is required to handle the extreme conditions associated with mining operations. These chains are used in various mining applications, including hoisting and hauling heavy loads, such as ore and minerals, in underground or surface mining environments. Manufacturing standards are GB / T12718-2009, PN-G-46701-1997, end Full compliance with ISO-610-1990 (E) and DIN22252-2012 standards.

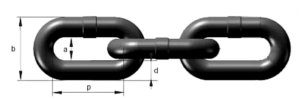

DIMENSIONS

| Dimensions | |||||

|

Chain specifications(mm)

|

diameter(mm)

|

Pitch(mm)

|

Minimum inner width(mm)

|

Maximum outer width(mm)

|

unit weight(mm)

|

|

14*50

|

14±0.4

|

50±0.5

|

17 | 48 | 4 |

|

18*64

|

18±0.5

|

64±0.6

|

21

|

60

|

6.6 |

|

22*86

|

22±0.7

|

86±0.9

|

26 | 74 | 9.5 |

|

24*86

|

24±0.8

|

86±0.9

|

28

|

79

|

11.6 |

|

26*92

|

26±0.8

|

92±0.9

|

30 | 86 | 13.7 |

|

30*108

|

39±0.9

|

108±1.0

|

34

|

98

|

18 |

|

34*126

|

34±1.0

|

126±1.2

|

38 | 109 | 22.7 |

|

38*137

|

38±1.1

|

137±1.4

|

42

|

121

|

29 |

|

42*146

|

42±1.3

|

146±1.5

|

46 | 137 | 36.5 |

|

42*152

|

42±1.3

|

152±1.5

|

46

|

133

|

35.3 |

|

48*152

|

48±1.4

|

152±1.6

|

52

|

154

|

48 |

| Mechanical behavior | |||||||

| Chain specifications | quality level | Load (KN) | Elongation (%) | Bending deformation deflection value (mm) | Fatigue life | ||

| Test load | Breaking load | Maximum elongation under test load (%) | Minimum elongation at break (%) | ||||

| 14*50 | B | 150 | 190 | 1.4 | 12 | 14 | 40000 |

| 14*50 | C | 200 | 250 | 1.6 | 12 | 14 | 40000 |

| 18*64 | B | 260 | 320 | 1.4 | 12 | 18 | 40000 |

| 18*64 | C | 330 | 410 | 1.6 | 12 | 18 | 50000 |

| 22*86 | B | 380 | 480 | 1.4 | 12 | 22 | 40000 |

| 22*86 | 2.C | 490 | 610 | 1.6 | 12 | 22 | 50000 |

| 22*86 | PW9 | 490 | 680 | 1.4 | 12 | 22 | 70000 |

| 24*86 | B | 460 | 570 | 1.4 | 12 | 24 | 40000 |

| 24*86 | 2.C | 580 | 720 | 1.6 | 12 | 24 | 50000 |

| 24*86 | PW9 | 580 | 815 | 1.4 | 12 | 24 | 70000 |

| 26*92 | B | 540 | 670 | 1.4 | 12 | 26 | 40000 |

| 26*92 | 2.C | 680 | 850 | 1.6 | 12 | 26 | 50000 |

| 26*92 | PW9 | 640 | 960 | 1.4 | 12 | 26 | 70000 |

| 26*92 | C-Super | 700 | 970 | 1.6 | 12 | 33 | 70000 |

| 26*92 | D-3 | 850 | 1060 | 1.9 | 12 | 33 | 70000 |

| 30*108 | B | 710 | 890 | 1.4 | 12 | 30 | 40000 |

| 30*108 | 2.C | 900 | 1130 | 1.6 | 12 | 30 | 50000 |

| 30*108 | PW9 | 850 | 1270 | 1.4 | 12 | 30 | 70000 |

| 30*108 | C-Super | 950 | 1280 | 1.6 | 12 | 38 | 70000 |

| 30*108 | D-3 | 1130 | 1410 | 1.9 | 12 | 38 | 70000 |

| 34*126 | B | 900 | 1140 | 1.4 | 12 | 34 | 40000 |

| 34*126 | 2.C | 1160 | 1450 | 1.6 | 12 | 34 | 50000 |

| 34*126 | PW9 | 1080 | 1640 | 1.4 | 12 | 34 | 70000 |

| 34*126 | C-Super | 1200 | 1650 | 1.6 | 12 | 43 | 70000 |

| 34*126 | D-3 | 1450 | 1810 | 1.9 | 12 | 43 | 70000 |

| 38*127 | B | 1130 | 1420 | 1.4 | 12 | 38 | 40000 |

| 38*127 | 2.C | 1450 | 1810 | 1.6 | 12 | 38 | 50000 |

| 38*127 | PW9 | 1360 | 2000 | 1.4 | 12 | 38 | 70000 |

| 38*127 | C-Super | 1500 | 2010 | 1.6 | 12 | 48 | 70000 |

| 38*127 | D-3 | 1810 | 2270 | 1.9 | 12 | 48 | 70000 |

| 40*152/146 | B | 1390 | 1740 | 1.4 | 12 | 42 | 40000 |

| 40*152/146 | 2.C | 1770 | 2220 | 1.6 | 12 | 42 | 50000 |

| 40*152/146 | PW9 | 1750 | 2500 | 1.4 | 12 | 42 | 70000 |

| 40*152/146 | C-Super | 1800 | 2520 | 1.6 | 12 | 53 | 70000 |

| 40*152/146 | D-3 | 2220 | 2770 | 1.9 | 12 | 53 | 70000 |

| 48*152 | 2.C | 2180 | 2950 | 1.6 | 12 | 48 | 40000 |

| 48*152 | C-Super | 2500 | 3250 | 1.9 | 12 | 56 | 70000 |

Key Features Of High-tension Round Link Chain For Mining

1. Material Strength:

These chains are typically made from high-strength alloy steel to withstand the high tension and abrasion encountered in mining operations.

2. Round Link Design:

The chain links are often designed in a round or circular shape, providing strength and durability. This design helps distribute the load evenly across the links.

3. Heat Treatment:

The chains may undergo heat treatment processes to enhance their hardness, strength, and resistance to wear.

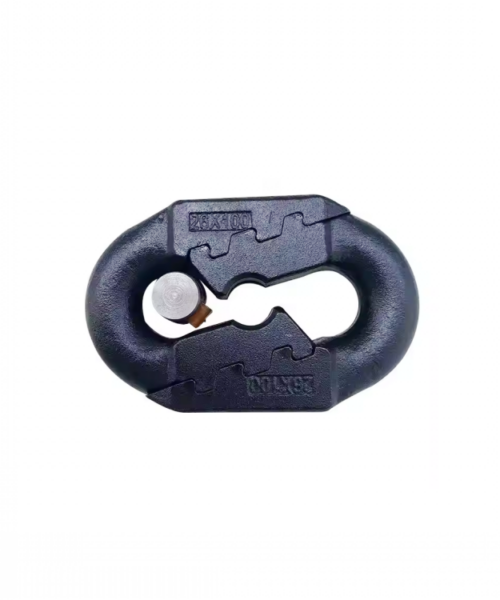

4. Welded Joints:

Welded joints between the links contribute to the overall strength and integrity of the chain. Proper welding is crucial to ensure the reliability of the chain in demanding mining conditions.

5. Corrosion Resistance:

Some chains may be coated or treated to resist corrosion, as mining environments can be harsh and expose equipment to moisture and corrosive substances.

6. Compliance with Standards:

High-tension round link mining chains should meet relevant industry standards and safety regulations to ensure their suitability for use in mining applications.

Reliable Mining Chain Supplier

Kailipu is one of the most professional rigging equipment supplier and exporter in China, specialized in all kinds of rigging hardware, welded chain, wire rope, lifting webbing sling, pulley, ect. High Tension Round Link Chain for Mining is one of the common welded chain. Kailipu produces and exports all kinds of round link mining chains. If you need a professional mining chain supplier, let Kailipu be your first choice. Kailipu will work with you to make better rigging, lifting and material handling products. For any more help, e-mail our specialists at [email protected] for assistance.

Related products

Mining Chain

Mining Chain

Mining Chain