——————————————WELDED CHAIN——————————————

Lifting Chains

Tie Down Chains

Hardware Chains

Marine Chains

Double Loop Chains

What Is The Welded Rigging Chain?

The welded rigging chain refers to a chain that is specifically designed and used for rigging purposes. Rigging generally involves the use of ropes, chains, and other equipment to lift, support, or move heavy objects. In the context of lifting and rigging, a rigging chain is a chain that is manufactured and rated for use in lifting and load-bearing applications.

Rigging chains are often made of high-strength materials, such as alloy steel, to ensure they can handle heavy loads safely. These chains may be equipped with various types of fittings, hooks, or attachments at each end to facilitate connections to lifting equipment, cranes, or the objects being lifted. It’s crucial to use the appropriate rigging chain with the correct load capacity and safety features for a particular lifting operation to ensure the safety of both personnel and property.

Professional Welded Chain Manufacturer in China

Kailipu is a top welded chain manufacturer and exporter in China. We supply various kinds of welding chains. Among them, the lifting chain, transport chain, hardware chain and marine chains are the most representative. Also, we produce a variety of specifications and tonnage, which covers almost all sizes you will need.

According to the different performance of the rigging chain, we usually divide them into overhead Lifting and non-overhead Lifting.

We have a full production line, not only can produce the standard type, but also do custom production. If you are looking for professional welded chain manufacturer, do not hesitate to contact us. We’ll Help Your Rigging & Welded Chain Business Succeed.

Related Rigging Accessories

FAQ

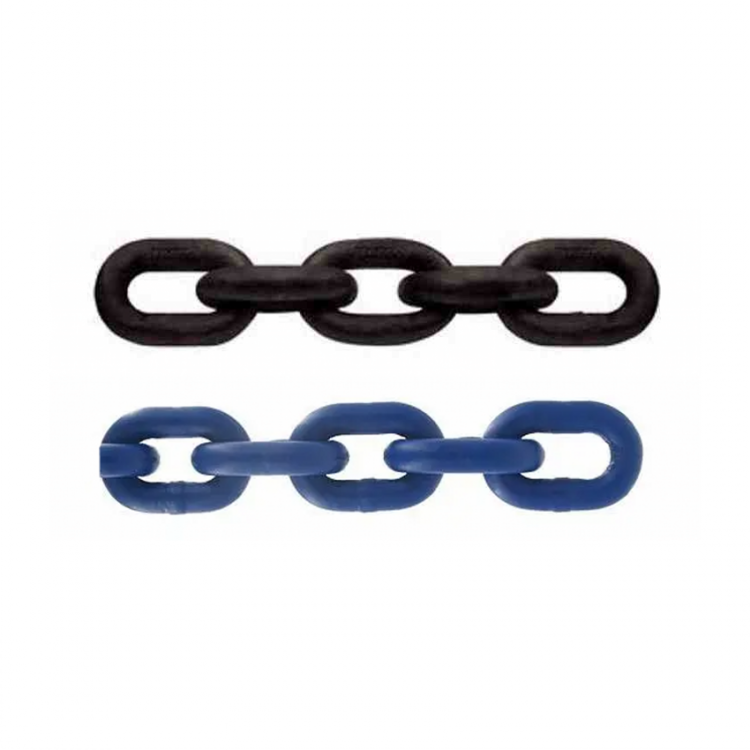

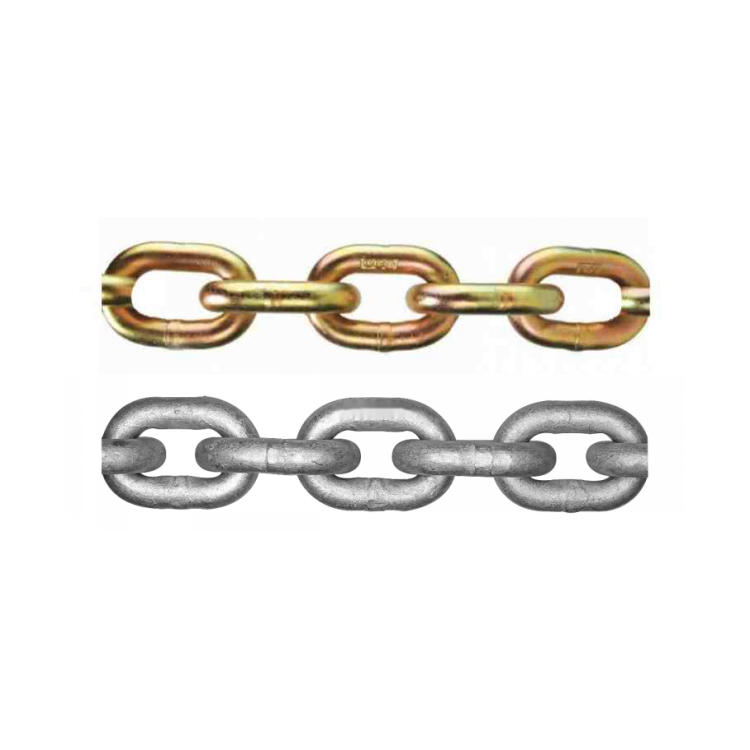

The lifting chain is made of high-quality alloy steel. Such as manganese steel, etc. They combine with some surface treatment processes to meet certain use requirements. And the surface treatment include: polishing, blackening, dipping, painting, hot-dip galvanizing, electroplating, Dacromet, etc.

The effect of the blackening process is to make the chain surface beautiful and not easy to corrode and rust. And the function of the hot-dip galvanizing is to form an alloy layer between the zinc and the substrate, thereby enhancing the adhesion of the zinc coating.

The material of the Grade 70 chain is carbon steel and heat-treated. And it has a recognizable golden chromate finish. Also, It is a trucker’s chain, built for fastening and placing. But it’s definitely not for carrying loads in high places. So we can’t use it for overhead lifting.

We all know that stainless steel has the best corrosion resistance. So it’s very suitable for ships and other corrosive environments. As for the alloy steel, its strength, hardness, plasticity and toughness is the best, so we use it to make lifting chains. Such as G80 EN818-2 lifting chain. And the last is carbon steel, which is the most widely used material. They are suitable for most purposes other than lifting, such as binding, transportation, towing and so on.