Malleable Iron Wire Rope Clip vs. Pig Iron: Which Material Should You Choose?

When it comes to securing wire ropes, wire rope clips are essential hardware components. They ensure the strength and stability of wire rope terminations in various industrial applications. However, not all wire rope clips are made from the same materials. Two common materials used in their bodies are malleable iron and pig iron.

In this blog, we’ll explore the key differences between malleable iron body and pig iron body wire rope clips, and how to choose the right one for your project.

What is a Malleable Iron Wire Rope Clip?

A malleable iron wire rope clip is a U-bolt clamp made from malleable cast iron, designed to secure wire ropes in various applications. Malleable iron undergoes heat treatment, which transforms its structure to make it more ductile and flexible. This results in a tough and durable material ideal for applications involving impact, bending, and tension.

Key Features of Malleable Iron Wire Rope Clips:

High Ductility: Malleable iron can withstand stress without breaking or cracking, making it ideal for heavy-duty applications.

Toughness: renxing This material can endure impact and shock, making it reliable for rigging and load-bearing purposes.

Corrosion Resistance: When galvanized, malleable iron wire rope clips offer good protection against corrosion, making them suitable for outdoor and marine environments.

Applications of Malleable Iron Wire Rope Clips:

- Heavy construction projects

- Industrial rigging

- Marine and outdoor use

- Lifting equipment

What is a Pig Iron Wire Rope Clip?

Pig iron is a raw, unrefined form of iron that is high in carbon content, making it more brittle compared to malleable iron. Pig iron is generally considered less suitable for applications that require flexibility or impact resistance. Due to its brittleness, it is less commonly used in demanding applications and is often more affordable.

Key Features of Pig Iron Wire Rope Clips:

Brittleness: Pig iron wire rope clips can break or crack under stress, making them less reliable for high-tension or load-bearing tasks.

Lower Cost: These clips are generally cheaper to produce, making them a budget-friendly option for non-critical, low-stress applications.

Limited Durability: Pig iron wire rope clips are less durable than malleable iron, especially when exposed to impact or bending forces.

Applications of Pig Iron Wire Rope Clips:

- Low-stress applications

- Temporary or inexpensive setups

- Non-safety-critical projects

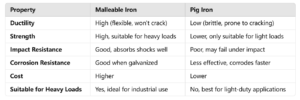

Malleable Iron Wire Rope Clip vs. Pig Iron: Key Differences

Choosing the Right Material for Your Wire Rope Clips

When deciding between a malleable iron body or a pig iron body wire rope clip, consider the following factors:

- Load Requirements: If your project involves heavy loads, repeated stress, or high tension, it’s essential to opt for malleable iron body wire rope clips. Their superior ductility and strength make them suitable for most rigging and lifting applications.

- Safety Concerns: In safety-critical applications, such as construction or marine rigging, malleable iron is the preferred material due to its ability to withstand deformation without breaking. Pig iron clips are generally not recommended for these uses, as their brittleness can lead to failure under stress.

- Cost Considerations: If you are working on a low-budget, low-risk project where the wire rope clip will not be subjected to heavy loads or stress, pig iron body clips can be a more cost-effective option. However, their lower strength and brittleness make them unsuitable for long-term or high-stress applications.

- Corrosion Resistance: In outdoor or marine environments, galvanized malleable iron clips provide better protection against corrosion, ensuring a longer lifespan and more reliable performance compared to untreated pig iron clips, which may corrode faster.

Conclusion:

In the world of wire rope clips, material choice plays a critical role in performance, durability, and safety. While malleable iron body wire rope clips offer superior strength, toughness, and flexibility for demanding applications, pig iron body wire rope clips may only be suitable for low-cost, temporary solutions with minimal stress requirements.

For most industrial, construction, and rigging applications, malleable iron is the better option, especially where safety and long-term durability are important. Choosing the right material will ensure that your wire rope clips perform reliably under the conditions they will face. If you’re unsure which option is right for your specific needs, feel free to reach out to us for advice or recommendations.

Contact our team at [email protected], Kailipu will work with you to make better Rigging, Lifting, Material handling products.

Related Links:

https://qd-kailipu.com/types-of-wire-rope-clips/

https://qd-kailipu.com/blog-a-comprehensive-guide-of-wire-rope-clamps/