Shackles for Lifting Screw Pin Bow Shackle

Technical Notes:U.S. Federal Specification(ASME B30.26)

Material: Body-Super Carbon Steel. Screw Pin-Alloy Steel

Safety Factor: 6 : 1 / 4 : 1

Processing: Body-Drop Forged / Quenched and Tempered

Screw Pin-hot/cold forging / Drop Forged / Quenched and Tempered

Finish: Body-Hot Dipped Galvanized / Powder Coated / Zinc Plated

Screw Pin-Powder Coated / Zinc Plated

Size: From 3/16”to 2-1/2”

Packing: Cartons or Gunny Bags and then on Pallets.

SHACKLES FOR LIFTING SCREW PIN BOW SHACKLE

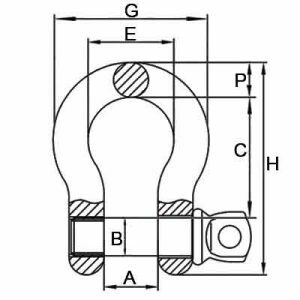

DIMENSIONS OF SHACKLES FOR LIFTING:

| Size | Working | Weight | Dimensions (in.) | Tolerance +/- | |||||||

| Load | |||||||||||

| Limited | |||||||||||

| (in.) | (t) | (lbs) | A | B | C | E | G | H | P | C | A |

| 3/16 | 1/3 | 0.06 | 0.38 | 0.25 | 0.88 | 0.6 | 0.98 | 1.47 | 0.19 | 0.06 | 0.06 |

| 1/4 | 1/2 | 0.1 | 0.47 | 0.31 | 1.13 | 0.78 | 1.28 | 1.84 | 0.25 | 0.06 | 0.06 |

| 5/16 | 3/4 | 0.19 | 0.53 | 0.38 | 1.22 | 0.84 | 1.47 | 2.09 | 0.31 | 0.06 | 0.06 |

| 3/8 | 1 | 0.31 | 0.66 | 0.44 | 1.44 | 1.03 | 1.78 | 2.49 | 0.38 | 0.13 | 0.06 |

| 7/16 | 1-1/2 | 0.38 | 0.75 | 0.5 | 1.69 | 1.16 | 2.03 | 2.91 | 0.44 | 0.13 | 0.06 |

| 1/2 | 2 | 0.72 | 0.81 | 0.63 | 1.88 | 1.31 | 2.31 | 3.28 | 0.5 | 0.13 | 0.06 |

| 5/8 | 3-1/4 | 1.37 | 1.06 | 0.75 | 2.38 | 1.69 | 2.94 | 4.19 | 0.69 | 0.13 | 0.06 |

| 3/4 | 4-3/4 | 2.35 | 1.25 | 0.88 | 2.81 | 2 | 3.5 | 4.97 | 0.81 | 0.25 | 0.06 |

| 7/8 | 6-1/2 | 3.62 | 1.44 | 1 | 3.31 | 2.28 | 4.03 | 5.83 | 0.97 | 0.25 | 0.06 |

| 1 | 8-1/2 | 5.03 | 1.69 | 1.13 | 3.75 | 2.69 | 4.69 | 6.56 | 1.06 | 0.25 | 0.06 |

| 1-1/8 | 9-1/2 | 7.41 | 1.81 | 1.25 | 4.25 | 2.91 | 5.16 | 7.47 | 1.25 | 0.25 | 0.06 |

| 1/1/4 | 12 | 9.5 | 2.03 | 1.38 | 4.69 | 3.25 | 5.75 | 8.25 | 1.38 | 0.25 | 0.06 |

| 1-3/8 | 13-1/2 | 13.53 | 2.25 | 1.5 | 5.25 | 3.63 | 6.38 | 9.16 | 1.5 | 0.25 | 0.13 |

PRODUCT DESCRIPTION

Hello!Welcome to visit our website, hope our products can make you satisfied.

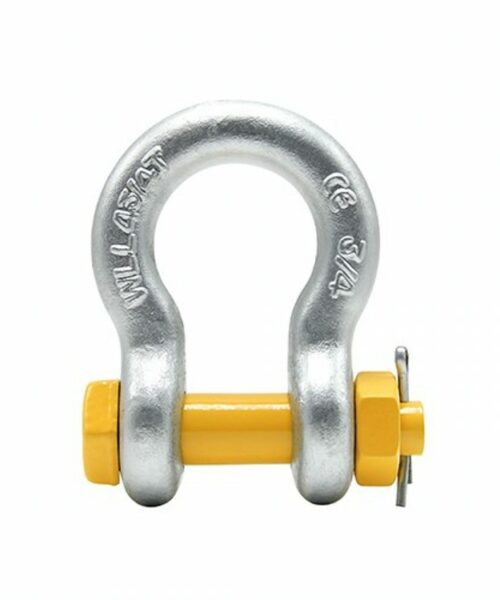

The bow shackle you are looking at is also known as anchor shackle. It is a type of connecting link used in rigging and lifting applications. They are typically made from high-strength materials such as steel or stainless steel to withstand heavy loads and provide durability. As its name It is an ‘O’ shaped metal link closed with a bolt, which is the most common type of rigging shackles.

Besides, Bow shackles are available in various sizes and weight capacities, allowing them to be used for different loads and applications. It can provide a strong and secure connection point between lifting or rigging equipment, such as chains, ropes, or slings. It is commonly used in industries such as construction, maritime, and off-road vehicle recovery.

SOME COMMON TYPES OF SHACKLES USED FOR LIFTING

- Screw Pin Shackles: These shackles have a threaded pin that can be easily unscrewed to open the shackle and attach it to the lifting equipment. The pin is then screwed back in to secure the connection.

- Bolt-Type Shackles: Bolt-type shackles have a removable bolt that passes through the ears of the shackle to secure the connection. These shackles are known for their high strength and are often used for heavy lifting applications.

- Safety Pin Shackles: Safety pin shackles have a pin that is secured with a safety cotter pin or a similar locking mechanism. This ensures that the pin remains in place during lifting operations, reducing the risk of accidental disconnection.

- Bow Shackles: Bow shackles have a “U” shaped design with a larger loop or “bow” shape, providing more clearance for attaching lifting equipment. They are commonly used when the lifting angle is at an angle or when more space is required to attach the equipment.

- D Shackles: D shackles have a “D” shaped design and are named so because they resemble the letter “D.” They have a narrower loop compared to bow shackles and are often used in situations where a compact connection point is required.

NOTE:

When using a bow shackle, it’s important to ensure that it is properly rated for the intended load and that it is securely closed and tightened. Proper inspection and maintenance of shackles are crucial to ensure their safe and effective use.