S505 Steel Swaging Sleeves

- For flemish eye wire rope splicing.

- Designed for low temperature toughness.

- Resists cracking when swaged (equals or exceeds stainless steel sleeves).

- Special processed low carbon steel.

- Do not use on wire rope size other than size shown.

S505 Steel Swaging Sleeves

S505 Steel Swaging Sleeves are designed for secure terminations of wire ropes, offering superior strength and durability. These sleeves are made from high-grade steel, making them ideal for heavy-duty applications in industries such as construction, marine, and rigging. When properly swaged, they provide a strong, permanent connection to wire ropes, ensuring safety and reliability.

Technical Specifications

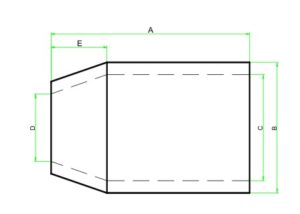

STEEL SWAGING SLEEVE

| Stock No. | Rope dia(mm) | Dimension(mm) | Dia. after swage | Weight | |||||

| (in.) | (mm) | A | B | D | E | C | (mm) | (kg/pc) | |

| S505-06 | 1/4 | 6.35 | 25.4 | 16.76 | 7.87 | 7.11 | 11.94 | 14.48 | 0.023 |

| S505-08 | 5/16 | 7.94 | 38.10 | 23.11 | 9.65 | 11.18 | 15.75 | 19.05 | 0.064 |

| S505-10 | 3/8 | 9.53 | 38.10 | 23.11 | 11.94 | 9.91 | 16.76 | 19.05 | 0.064 |

| S505-11 | 7/16 | 11.11 | 50.80 | 30.99 | 13.46 | 16.51 | 21.59 | 25.65 | 0.150 |

| S505-13 | 1/2 | 12.70 | 50.80 | 30.99 | 16.00 | 14.22 | 23.11 | 25.65 | 0.130 |

| S505-14 | 9/16 | 14.29 | 69.85 | 37.34 | 17.78 | 16.00 | 26.16 | 31.50 | 0.290 |

| S505-16 | 5/8 | 15.88 | 69.85 | 37.34 | 19.05 | 16.00 | 27.69 | 31.50 | 0.260 |

| S505-19 | 3/4 | 19.05 | 81.03 | 43.69 | 23.11 | 21.34 | 32.51 | 37.08 | 0.400 |

| S505-22 | 7/8 | 22.23 | 90.42 | 51.56 | 26.16 | 25.40 | 38.86 | 42.67 | 0.600 |

| S505-26 | 1 | 25.40 | 101.60 | 57.91 | 29.46 | 28.70 | 43.69 | 49.02 | 0.890 |

| S505-28 | 1-1/8 | 28.58 | 121.92 | 63.50 | 32.51 | 31.75 | 49.28 | 54.10 | 1.180 |

| S505-32 | 1-1/4 | 31.75 | 131.83 | 70.61 | 36.58 | 35.81 | 54.86 | 58.93 | 1.610 |

| S505-35 | 1-3/8 | 34.93 | 147.57 | 76.20 | 39.62 | 39.62 | 60.45 | 64.00 | 1.920 |

| S505-38 | 1-1/2 | 38.10 | 158.75 | 82.55 | 42.93 | 42.93 | 66.80 | 68.83 | 2.270 |

| S505-45 | 1-3/4 | 44.45 | 184.15 | 97.54 | 49.28 | 50.04 | 79.50 | 78.74 | 3.660 |

| S505-50 | 2 | 50.80 | 215.90 | 111.25 | 57.15 | 57.15 | 92.20 | 90.42 | 5.140 |

| S505-57 | 2-1/4 | 57.15 | 242.82 | 127.76 | 63.50 | 64.26 | 102.36 | 104.65 | 8.790 |

| S505-64 | 2-1/2 | 63.50 | 266.70 | 139.70 | 69.85 | 71.37 | 114.30 | 114.30 | 10.680 |

| S505-70 | 2-3/4 | 69.85 | 292.10 | 146.05 | 76.20 | 78.49 | 120.65 | 119.38 | 12.710 |

| S505-76 | 3 | 76.20 | 304.80 | 152.40 | 82.55 | 85.85 | 127.00 | 125.98 | 13.350 |

| S505-82 | 3-1/4 | 82.55 | 330.20 | 165.10 | 98.04 | 89.92 | 137.92 | 136.40 | 16.500 |

| S505-89 | 3-1/2 | 88.90 | 355.60 | 177.80 | 98.55 | 100.08 | 148.34 | 146.56 | 21.060 |

| S505-95 | 3-3/4 | 95.25 | 381.00 | 190.50 | 103.12 | 107.95 | 160.27 | 158.24 | 24.970 |

| S505-100 | 4 | 101.60 | 406.40 | 206.50 | 111.25 | 114.30 | 172.97 | 169.93 | 30.870 |

| S505-115 | 4-1/2 | 114.30 | 457.20 | 231.90 | 123.95 | 128.52 | 194.56 | 189.23 | 45.400 |

| S505-130 | 5 | 127.00 | 508.00 | 267.21 | 139.70 | 143.00 | 221.74 | 210.31 | 66.000 |

| S505-150 | 8 | 152.40 | 609.60 | 318.52 | 165.10 | 171.45 | 259.08 | 252.22 | 123.00 |

For eye wire rope splicing.

Designed for low temperature toughness.

Resists cracking when swaged (equals or exceeds stainless steel sleeves).

Special processed low carbon steel.

Key Features of Steel Swaging Sleeves

High Tensile Strength: Made from S505 steel, these swaging sleeves provide exceptional load-bearing capabilities.

Durable and Reliable: Resistant to wear and tear, ensuring long-lasting performance even in demanding conditions.

Precision Swaging: Ensures a secure and strong grip on wire ropes for safe lifting and load handling.

Corrosion Resistance: Suitable for outdoor and marine environments where resistance to rust and corrosion is critical.

Multiple Sizes Available: Accommodates a variety of wire rope diameters for different application needs.

Applications of Steel Swaging Sleeves

Marine Industry: Ideal for use in mooring and rigging systems where corrosion resistance and strength are crucial.

Construction: Widely used in lifting and load-bearing applications, such as cranes, hoists, and building equipment.

Industrial Machinery: Used in machines that require secure wire rope terminations under heavy loads.

Mining: Commonly used in the mining industry for hoisting and securing heavy loads.

Transport and Logistics: Ensures secure wire rope connections for cargo handling and transportation systems.

How to Use:

S505 Steel Swaging Sleeves are recommended for use with 6 x 19 or 6 x 37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC or IWRC wire rope. Before using any National Swage fitting with any other type lay, construction or grade of wire rope, it is recommended that the termination be destructive and documented to prove the adequacy of the assembly to be manufactured.

Installation Guide:

- Swaging Required: Use appropriate swaging tools to securely attach the steel sleeve to the wire rope.

- Ensure Proper Fit: Confirm the sleeve size matches the wire rope diameter for maximum safety.

Why Choose Our Steel Swaging Sleeve?

Superior Strength: Manufactured from high-quality S505 steel, offering exceptional performance under heavy loads.

Durable and Long-Lasting: Designed for demanding environments where long-term reliability is essential.

Competitive Pricing: Affordable solutions for bulk orders, ideal for importers and distributors.

Global Shipping: We offer fast and reliable delivery to customers worldwide.

Need high-quality S505 Steel Swaging Sleeves for your next project? Contact us today to place a bulk order at competitive prices. We ship globally and offer flexible delivery options to meet your needs.

Contact our team at [email protected], Kailipu will work with you to make better Rigging, Lifting, Material handling products.

Related Links:

Related products

Wire Rope Sleeves

Wire Rope Sleeves

Wire rope clips