Synthetic Rope Thimbles

- Material Options: Galvanized Steel, Stainless Steel, Mild Steel

- Standard: DIN, ASTM, or custom specifications as required

- Size Range: From 10mm to 112mm (custom sizes available on request)

- Finish: Galvanized (zinc-plated), Stainless Steel (passivated), Plastic spraying

- Shape: Tubular with gusset for enhanced reinforcement.

- Applications: Termination of wire ropes in lifting, rigging, and securing loads.

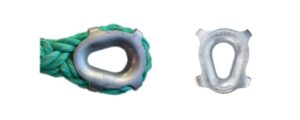

Synthetic Rope Thimble

Synthetic rope thimbles also known as semi enclosed thimbles. They are specially designed components that provide protection and structural integrity to synthetic rope loops, commonly used in marine, industrial, and outdoor settings. With a unique design to withstand high loads without damaging the rope fibers, synthetic rope thimbles are essential for maintaining safety and prolonging rope life.

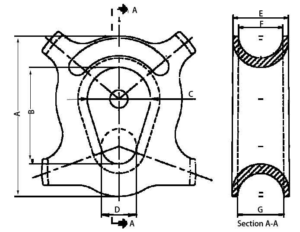

Technical Specifications

| ROPE DIAMETER(mm) | A | B | C | D | E | F | G | WEIGHT(kg)APPROX |

| Ø16/Ø22 | 111.5 | 65 | 32 | 10 | 37 | 28 | 35 | TBA |

| Ø24/Ø30 | 146.5 | 90 | 51 | 28 | 47 | 37 | 40 | 1.25 |

| Ø32/Ø40 | 196 | 127 | 85 | 42 | 57 | 46 | 50 | 2.25 |

| Ø44 | 205 | 140 | 86 | 42 | 64 | 52 | 54 | 3.4 |

| Ø48/Ø56 | 247 | 149 | 92 | 44 | 85 | 70 | 76 | 5.3 |

| Ø64 | 274.5 | 159 | 102 | 54 | 95 | 76 | 79 | 7.9 |

| Ø72 | 316 | 194 | 120 | 68 | 102 | 83 | 89 | 12.25 |

| Ø80 | 349 | 217.5 | 127 | 70 | 108 | 89 | 98 | 14.45 |

| Ø88/Ø96 | 403.5 | 241 | 156 | 86 | 140 | 114 | 117 | 26.4 |

| Ø112 | 477.5 | 280 | 184 | 104 | 170 | 140 | 145 | 30 |

Key Features of Synthetic Rope Thimble

Rope-Friendly Design: Smooth, non-abrasive design that prevents fraying and extends the lifespan of synthetic ropes.

Lightweight & Strong: Made from materials such as polymer composites or coated metals for excellent strength-to-weight ratio.

Corrosion-Resistant: Suitable for wet and marine environments due to corrosion-resistant materials.

Various Sizes Available: Suitable for synthetic ropes of different diameters.

UV and Weather Resistant: Designed to withstand prolonged exposure to sunlight, saltwater, and varying weather conditions.

Applications

Marine & Boating: Ideal for mooring lines, docking lines, and other marine rigging uses.

Industrial & Rigging: Used in lifting, hoisting, and securing heavy loads with synthetic ropes.

Recreational Activities: Perfect for rock climbing, zip-lining, and other outdoor rope activities.

Agricultural Use: Reliable for securing synthetic ropes used in farming and forestry equipment.

Rescue & Safety Operations: Essential in emergency services for durable and safe rope connections.

How to Use:

- Step 1: Choose the correct thimble size based on your synthetic rope diameter.

- Step 2: Insert the synthetic rope into the thimble, ensuring it fits snugly.

- Step 3: Use appropriate connectors (e.g., shackles or clips) to secure the rope loop in place.

- Step 4: Inspect the installation to ensure that the rope and thimble are properly aligned and load-ready.

Why Choose Us for Synthetic Rope Thimbles:

Industry Expertise: With years of experience in producing high-quality rigging and lifting accessories, we offer products designed to meet rigorous industry standards, ensuring safety and reliability.

Premium Quality Materials: Our synthetic rope thimbles are crafted from durable, corrosion-resistant materials, built to withstand demanding conditions and extend rope lifespan.

Customization Options: We understand that different projects have unique requirements, so we offer customizable solutions tailored to meet your specific needs and application requirements.

Global Shipping and Reliable Support: Serving clients worldwide, we ensure timely delivery and provide dedicated support to assist you at every stage, from selection to post-purchase service.

Competitive Pricing for High-Value Solutions: By balancing quality and affordability, we deliver value-packed solutions, helping you optimize performance while staying within budget.

Ensure the durability and safety of your rigging setup with our high-quality synthetic rope thimbles. Kailipu specializes in the production of various rigging and wire rope fittings. Contact us today for bulk orders and competitive pricing on industrial-grade tube thimbles. Contact our team at [email protected], Kailipu will work with you to make better Rigging, Lifting, Material handling products.

Related Links:

Related products

Wire rope clips

Wire rope clips

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles

Wire Rope Thimbles