Shackles are one of the most common rigging accessories. They come in different sizes to accommodate various load capacities. Therefore, the size of a shackle can typically determine by its working load limit (WLL).

Today we will learn about the sizes of shackle from three aspects: the general classification, dimensions and safe working tension.

The General Classification Of Shackles

First of all, let’s have a general understanding of the classification of shackles. We all know that there are metric and imperial hardware on the market, and the same is true for shackles. We usually refer to imperial shackles as US type shackles, such as 1/4”, 1/2”, 1”, 3”, etc. And those expressed in metric system such as M6, M8, M12, M25 are call European style. Of course, Chinese and Japanese standards are also expressed in metric system.

In addition, from the shape point of view, we can divide them into bow shape (also call anchor type) and D-shape (also call Dee, Chain type). These two types are only different in shape, and the same specification corresponds to the same working tension.

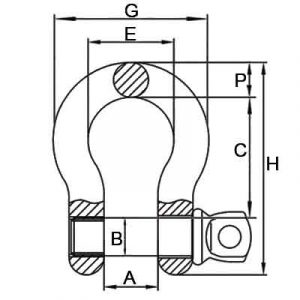

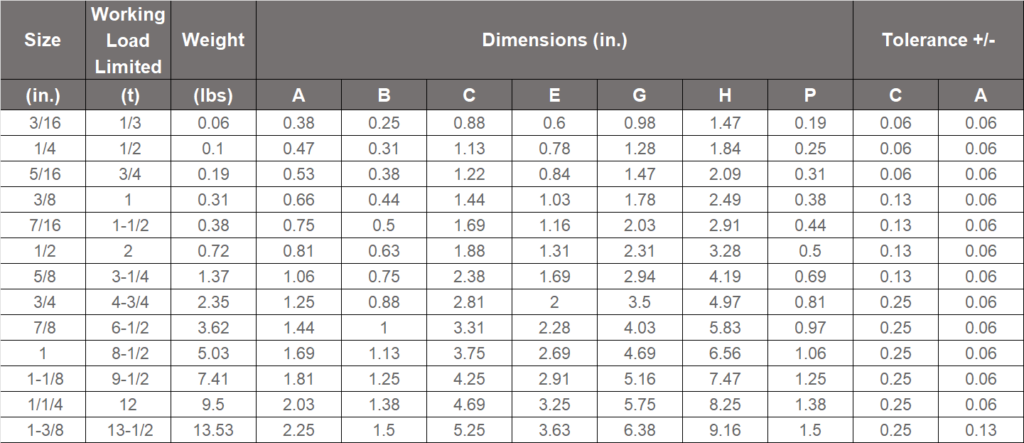

The Sizes or Dimensions of Shackle

Let’s take the size chart of the shackle in the above figure as an example. We can see the imperial size in the specification column, and this data is actually the size of the shackle body diameter (“P” column). And each diameter has a corresponding working load limit data. For example, size 3/16”, working load limit 1/3t. The working load limit corresponding to each size is fixed. Therefore, when expressing the sizes of a shackle, you can use its material diameter or its working tension, and the manufacturer can understand it very well.

What is WLL in shackle sizes?

After reading the above explanation, I think you should be able to understand the specification of a shackle well. Finally, we add a little more about the interpretation of a common abbreviation WLL.

“Working Load Limit (WLL) is the maximum working load designed by the manufacturer. This load represents a force that is much less than that required to make the lifting equipment fail or yield. People usually calculate WLL by dividing MBL by a safety factor (SF). “

So, WLL is a safe working load. As long as it is used within this range, it is a safe operation. In addition, there are two data of safety factor, and minimum breaking strength(MBS), which we can also understand.

Safety factor & MBS

For the safety factor of US type shackles, there are usually two safety factors: 4:1 and 6:1. They indicate that the force capable of breaking the shackle is 4 times and 6 times the marked working load limit. For example, shackle size 3/16” WLL 0.33Ton, 4:1 means its breaking force is 0.33 times 4, and 6:1 is 0.33 times 6. Of course, the price with a high safety factor will also be higher. In actual use, a reasonable choice can be made according to the application scenario.

Note:

Please note that these load capacities are general guidelines, and specific shackles may have different ratings depending on their design, material, and manufacturer. It’s crucial to consult the manufacturer’s documentation and guidelines to ensure you’re using the correct shackle size and capacity for your specific application.

Kailipu focuses on the production and development of various types of shackles. We have a full production line. Not only can produce the standard type, but also do custom production. If you are looking for a professional shackle supplier, do not hesitate to contact us at [email protected]