Turnbuckle, also known as turnbuckle screws, rigging, and tight wire buckles. It is a type of mechanical device use to adjust the tension or length of ropes, cables, rods, or other tensioning systems. It consists of two thread eye bolts or hooks with a center body that can rotate, which allows the distance between the two ends to easily adjust.

Types of Turnbuckles

Our most common turnbuckles have hooks and eyes at the end. Among them, the eye-eye type is use for occasions where disassembly is infrequent. And the hook type is use for occasions where disassembly is frequent. The hook-and-eye type is use in occasions where one end is often disassemble and the other end is not frequently disassemble.

Turnbuckles are mainly divided into cast malleable steel, ordinary carbon steel, and forging methods. There are mainly two types of ordinary carbon steel and forging in the market. Carbon steel turnbuckles are mainly use for static binding and stability in unimportant occasions. Scenes, such as garden wind protection, agricultural greenhouses, etc. Forged turnbuckles are use for lifting, freight lashing and reinforcement. Such as cargo bundling in logistics, sling connection, steel structure cable-rod connection, etc.

Surface treatment: Generally, there are two kinds of electroplating and hot-plating, which mainly play the role of preventing corrosion. Hot plating is more expensive than electroplating, but has better corrosion resistance. US type forged turnbuckles are usually in hot-dip galvanize surfaces. Other styles are usually electro-galvanizing.

How To Use a Turnbuckle?

Turnbuckles are commonly use in various applications, such as construction, engineering, rigging, and even in some sports and recreational activities. So how to use it correctly? We can refer to the following steps:

1.Identify the components

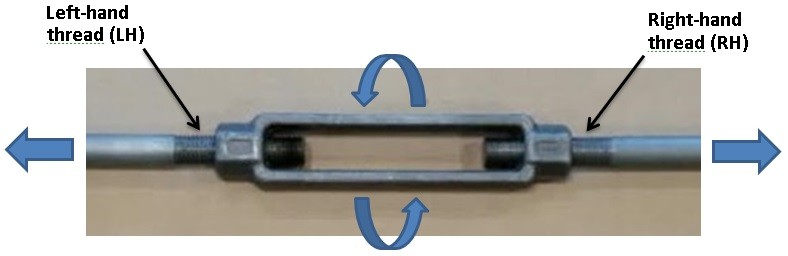

A typical turnbuckle consists of two thread end fittings (often with eye bolts or hooks) and a central body with right-hand threads on one end and left-hand threads on the other. The central body has a center slot that allows it to rotate and adjust the distance between the end fittings.

2.Inspect the turnbuckle

Before using a turnbuckle, ensure that it is in good condition and not damage. Check for any signs of wear or deformation that could compromise its strength and functionality.

3.Attach the turnbuckle

Connect one end to one fixed anchor point and the other end to the object or structure you want to tension or adjust. For example, if you’re using it to tighten a wire fence, attach one end of the turnbuckle to a fence post and the other end to the wire.

4.Adjusting the tension

To adjust the tension or length, rotate the central body. Turning it clockwise will tighten the turnbuckle and decrease the distance between the end fittings, increasing the tension. Turning it counterclockwise will loosen the turnbuckle and increase the distance between the end fittings, reducing tension.

5.Achieve the desired tension

Adjust the turnbuckle until you achieve the desired level of tension in the rope, cable, or structure. Use a tension gauge or measure the distance between the end fittings to ensure consistent tension if required.

6.Secure the turnbuckle

Once you’ve reached the desired tension, lock the turnbuckle in place. Many turnbuckles have locking nuts on each end of the central body that can tighten to prevent the turnbuckle from unintentionally rotating and changing the tension.

7.Periodic inspection

Regularly inspect the turnbuckle to ensure it remains in good condition and maintains the desired tension. Depending on the application, turnbuckles may experience wear over time and may need replacement if they show signs of damage or weakening.

Generally speaking, turnbuckle is a hardware device with simple structure, low cost, convenient use and strong practicability. During use, please remember that the swivel buckle should be use within its state load capacity and with proper safety precautions to avoid accidents or malfunctions. If you are not sure how to use the turnbuckle correctly, it is best to seek guidance from a professional or experienced person in the related field.

Kailipu focuses on the production and development of various types of turnbuckles. We have a full production line. Not only can produce the standard type, but also do custom production. If you are looking for a professional rigging turnbuckle supplier, do not hesitate to contact us at [email protected].