Shackles are one of the most common connectors in lifting operations. It can make lifting operations more secure and flexible. The seemingly simple shackle shoulders the burden. Therefore, the safety of lifting operation is not only closely related to the quality of the sling itself, but also closely related to the shackle. So what details do we need to clarify before purchasing shackles? Let’s take a look at it together.

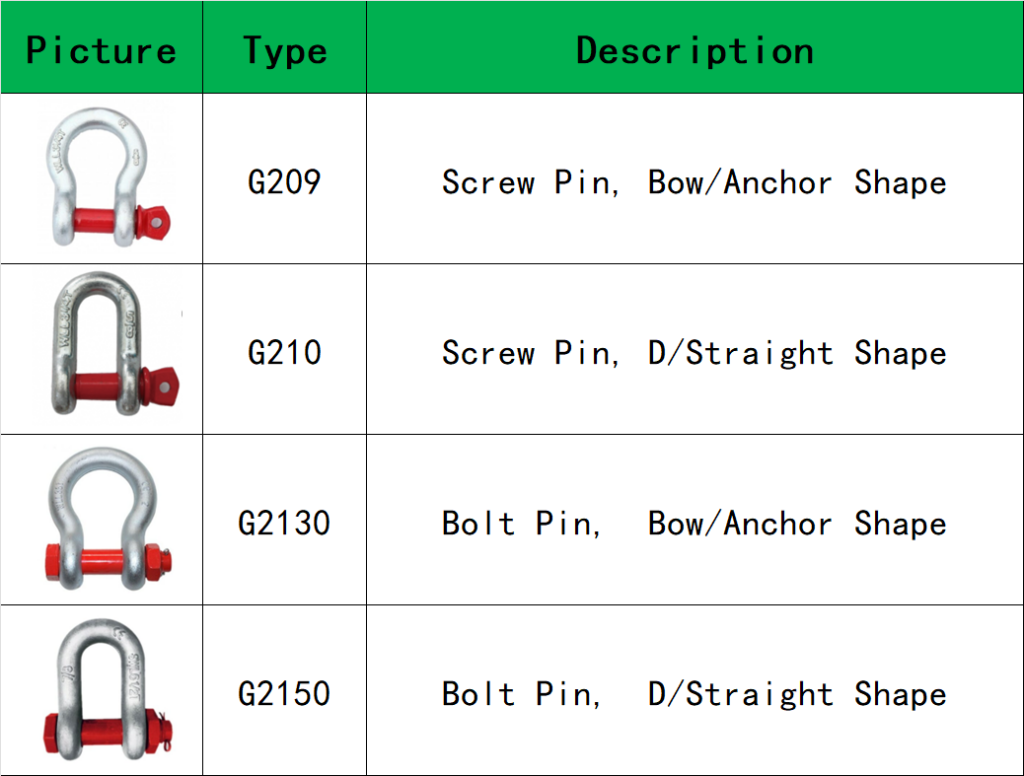

1.Types of US shackles

Common US type shackles can be divided into bow and straight (also known as D type) in shape. Then according to the different pins it uses, it can be divided into screw pins and bolt pins. For a more convenient description, we can also use their code names. See below:

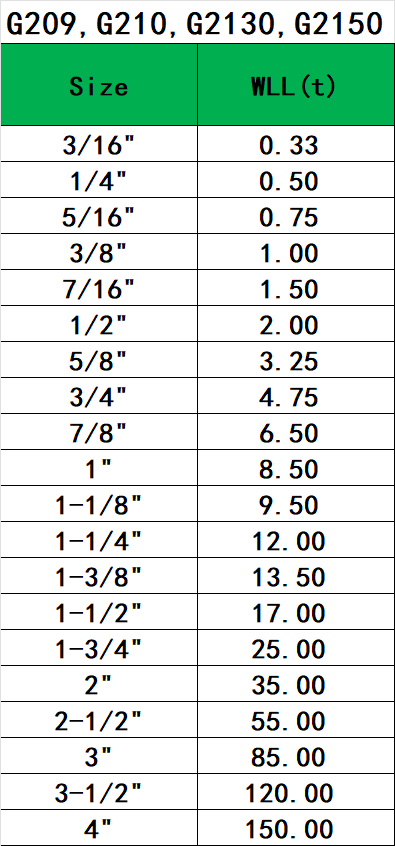

2. Specifications

Specification we can use the safety working load (WLL) or its material diameter size to express. It’s even better if you can do both. For the above four types of shackles, the WLL to the same material diameter is the same. For details, please refer to the following table:

3. Safety factor

Many people may only pay attention to the safe working tension and ignore the safety factor of the shackle. So what is the safety factor? We know that WLL refers to the safe range within which a shackle can be allowed to work. This value is a safe value rather than a limit value. The limit value is measured during the tensile test. It is the ultimate bearing capacity of the shackle. The safety factor is the ratio of the ultimate application force to the WLL. Our current common safety factors are 6:1 and 4:1. For example, the WLL of a shackle is 5 tons, and the safety factor is 6:1, then its ultimate force is 30 tons (5*6=30).

The reason why shackles are widely used is that they have a very high safety factor, and a high safety factor is also the key to ensuring operation safety.

4. Surface treatment

Surface treatment is well understood. Like other items, the surface treatment of the shackle includes electro-galvanized(EG), hot-dip galvanized(HDG), sprayed, self colored, etc. Among them, EG and HDG are used more frequently. In addition, the price of HDG is higher than that of EG, although the brightness and smoothness of electro-galvanizing look better. However, the thickness of the zinc layer of hot-dip galvanizing is thicker, and its corrosion resistance is better than that of electroplating.

Summarize

The above four points are the basic details we need to know when purchasing US type shackles. If you need more professional shackle services, please e-mail our specialists at [email protected] for assistance.