Wire rope is a complex mechanical device, different structures and combinations of wire ropes have different characteristics. Today let’s have a simple understanding of the components and structure of the wire rope. Yet this article mainly focuses on the explanation of some nouns and abbreviations of steel wire ropes. And it can give us some basic understanding of the wire rope specifications construction.

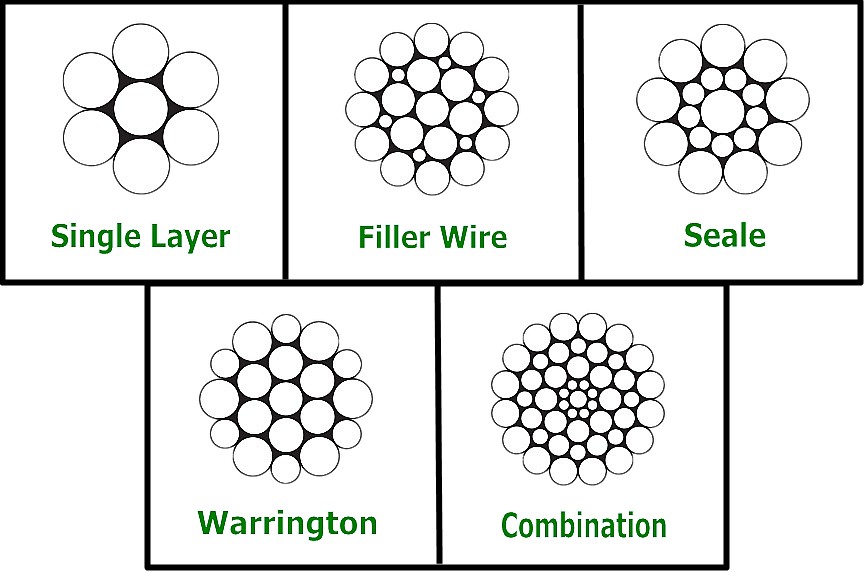

Types of Strand

The type of strand is characterize by the arrangement of wires in the strand. There are five basic types of strand design uses in wire ropes. A wire rope can be one of them, or it may be a combination of two or more. The five basic types are:

Single Layer:

The most common example is a 7 wire strand with a single-wire center. And six wires of the same diameter around it.

Filler Wire

Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are lay in valleys of the inner wire.

Seale

Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington

Two layers of wires around a center with one diameter of wire in the inner layer. Then two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns of the inner layer.

Combination

A combination strand is constructe using any combination of two or more of the patterns listed above.

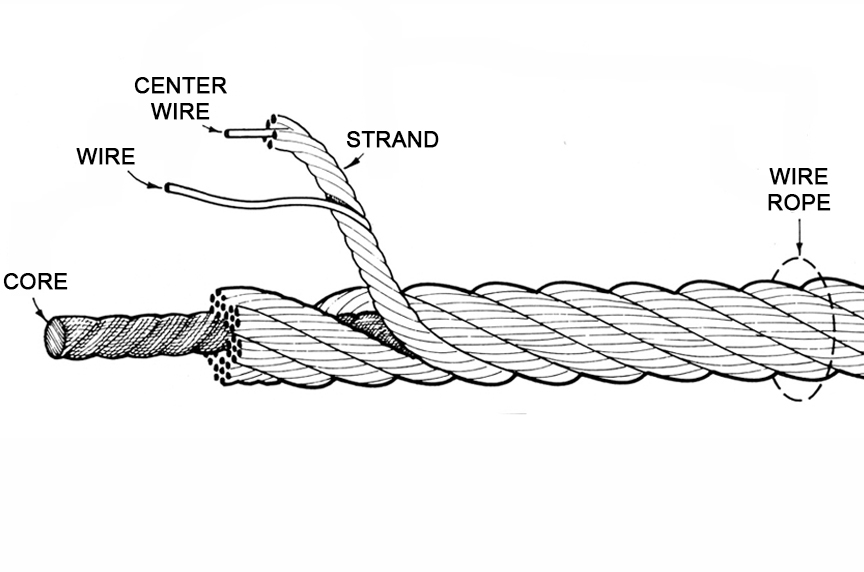

Type of Core

We can divide the core of the wire rope into fiber core (FC) and steel core.

Material of Fiber cores are natural (NFC) or synthetic polypropylene fiber (SFC). In that, they can provides greater elasticity than steel cores but is more likely to break. Therefore, it is not recommende for high temperature environment.

A steel core can be an independent wire rope (WSC) or an individual strand (IWRC). And the steel cores are best suite for applications where a fiber core may not provide adequate support. Or in an operating environment where temperatures could exceed 180° F.

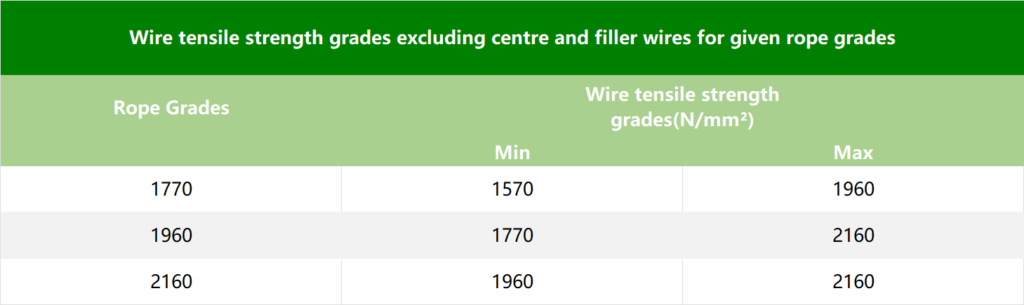

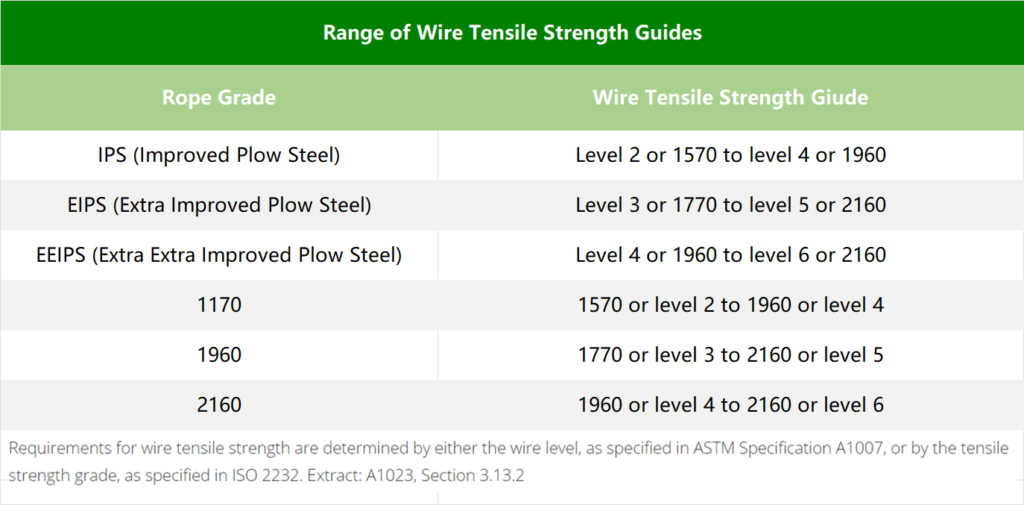

Grade of Rope-wire rope specifications construction

The term “rope grade” is often use in international standards to group wire ropes. This practice can confuse rope users, both when they specify/describe the rope and when they receive the rope. Below we will explain the two levels that are more common in the world.

EUROPEAN STANDARDS E.G., EN 12385 SERIES

Rope grade (Rr ): is a level of requirement of breaking force which is designate by a number (e.g. 1770, 1960, 2160) Extract: EN 12385-2 clause 3.10.11

Wire tensile grade (R): a level of requirement of tensile strength of a wire and its corresponding range. We can designate the value according to the lower limit of tensile strength. And we use it when determining the calculate minimum breaking force or calculated minimum aggregate breaking force, expressed in N/mm2. Extract: EN 12385-2 clause 3.1.10.

For those ropes where a grade is applicable, the wire tensile grades of shall be subject to the limits below. Extract: EN 12385-4 clause 5.2.1

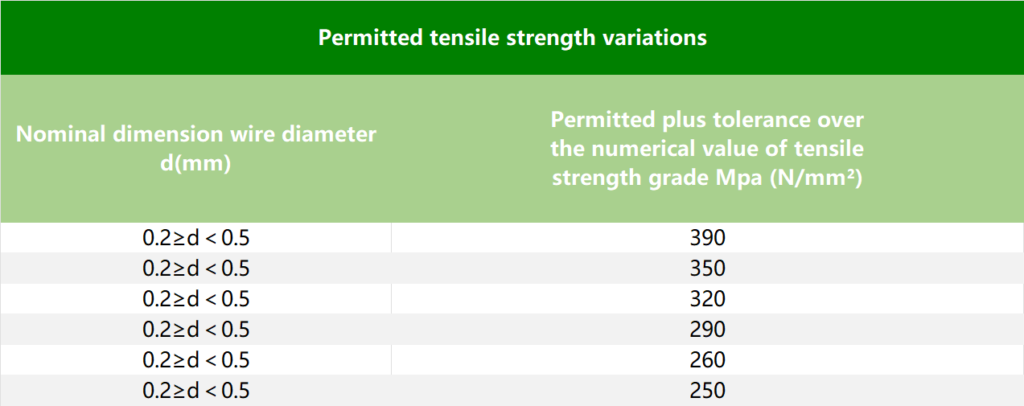

America Standard A 1023

Stranded Carbon Steel Wire Ropes for General Purposes is the most widely use rope standard in North America. And we distribute them by ASTM through governance of American National Standards Institute (ANSI). A1023 also specifies the rope grades in a similar way to the EN standard. For those ropes the tensile strength grade of the wires shall be subjecte to the limits in the table below:

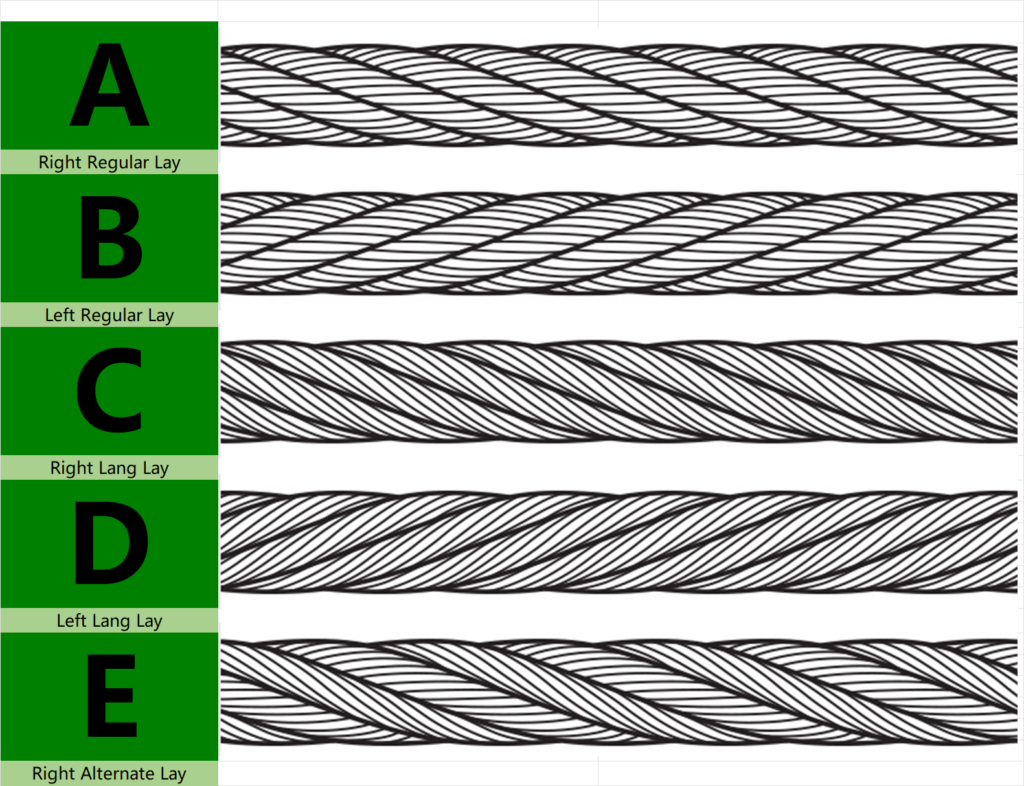

Direction and Type of Lay

Direction and type of lay refer to the way the wires lay to form a strand. And how the strands lay around the core (regular lay, lang lay, or alternate lay).

- Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces. And they are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

- Lang Lay – The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

- Alternate Lay – The wire rope consists of alternating regular lay and lang lay strands—used mainly for special applications.

Wire Rope Specifications Construction China Supplier

The above factors contribute to the different performance of the wire rope. Including strength, flexibility, wear resistance, corrosion resistance, and rotation resistance. We can choose the right wire rope according to the use.

Kailipu as China’s professional wire rope suppliers, produce and export of a variety of high quality wire ropes.

If you are looking for the required wire rope products for your project, do not hesitate to contact us. More professional services, please e-mail our specialists at [email protected] for assistance.