———————————Wire Rope Clips/Cable Clamps———————————

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Wire rope clips

Precautions in Purchasing Wire Rope Clips

1. Unlike most rigging hardware, most wire rope clamps are not tested for tension. We can usually do a torque test for the clips. That is to say, whether the clamp head has enough force to clamp the wire rope. This is very important, but its often overlooked by many purchases.

2. The body of many clamps is cast from malleable steel, and its surface is rough and has weak anti-corrosion properties. A little rust will occur on the galvanized layer in the rainy season or in a humid environment, that is, the surface of the galvanized layer white rust. This is not uncommon. Therefore, when purchasing in bulk, it is best to pack it with a brand-new electroplated clamps. At the same time, pay attention to placing it in a dry environment.

3. Choice of packaging: The most economical packaging for the wire rope clips is a woven bag (about 50*40cm). In addition, there are plastic bags or inner boxes + cartons suitable for retail, heat-sealed cards suitable for supermarket hanging, etc. When purchasing, you can make the best choice according to the needs and costs of your target customers.

Top Wire Rope Clip Supplier in China

Kailipu is one of the most professional cable clamps suppliers in China. And we manufacture malleable and forged types for the most. Among them, the DIN 741, DIN 1142, US type malleable and drop forged type are the most representative. Also our specifications range from 3mm to 50mm, which covers almost all sizes you will need.

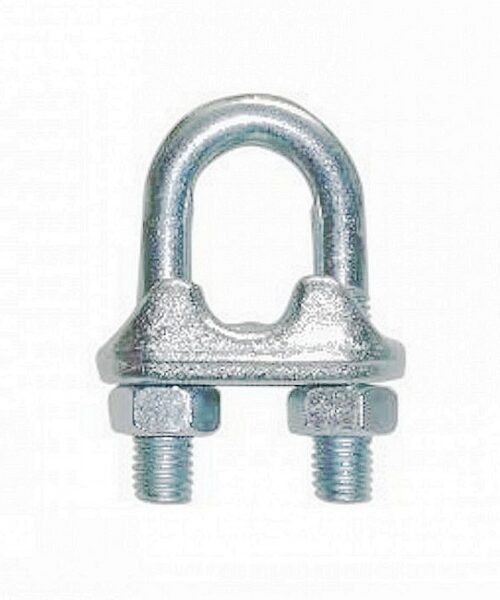

Cable clamp, also call wire rope clip, U-clips, U-clamp,wire rope clamp. It is a common wire rope fittings. We use it to fix the loose end of the loop back to the wire rope. They usually consists of a U-shaped bolt, a forged or cast saddle and two nuts. The two layers of wire rope are place in the U-bolt.

We supply hundreds of high-quality rigging hardware and wire rope fittings. Moreover, we also have a full production line. Not only can produce the standard type, but also do custom production. We take pride in crafting wire rope clips that set industry standards for reliability and performance. Our commitment to excellence is embedded in every part. If you are looking for a professional rigging hardware and wire rope fittings supplier, do not hesitate to contact us at [email protected]

Related Categories

FAQ

Cable clamps sometimes refer to cable stops or cable clips. And we usually use it to clamp down on wire rope during construction projects.

First you should choose a reliable and professional rigging hardware manufacturer.

Secondly, think about your work environment. In other words, where you want to use the wire rope clip?

Finally, you need to consider the load specifications. Also, you shouldn’t use clips for any permanent rigging or lifting applications. Because they are suited only for temporary load applications.

1. Drop Forged Galvanized

- They cost less than stainless steel wire rope clips.

- They are more suited for outdoor environments.

- But, they are not as corrosion resistant as their stainless-steel variants.

2. Malleable Galvanized

- They can be use in outdoor environments.

- But they are not as corrosion resistant as other types of wire rope clamps.

- Their surface can develop rust quickly when exposed to rain, snow, salty air, or saltwater environments.

3. Stainless Steel

- These are the most corrosion-resistant wire rope clamps.

- Highly resistant to surface rust, even in saltwater environments, they are best suite for outdoor environments.

- As stainless steel is costly, they are a little expensive compare to other types of clamps.

Typically, the distance between the clips is about six wire rope diameters, to give adequate holding power. We need to tighten the clips before the rope is placed under tension. After the load is placed on the rope, tighten the clips again to take care of any lessening in rope diameter cause by tension of the load.